Would YOU work for you?

This month’s theme is focused on hiring great people. It all sounds good, but let’s have a look in the back of your plant. Would you work for yourself? Is your plant clean, comfortable and inviting? Do the machines work properly? Are the people friendly? You spend more hours awake per day in that place than you do at home. Do your workers hate their jobs?

Here are some suggestions to help you make it a better place to work.

Clean your own area

Whose job is it to pick up the hangers that fall behind the press? Who is responsible to clean the press table and the area around the press?

The presser. Good, but do you provide the time and supplies to do that? Do you ever check to see if it is clean?

We used to pick a Friday morning every month and start the day with a plant cleanup. Everyone was involved in cleaning their area – no exceptions. They would vacuum, blow with compressed air, dust and wipe down or whatever they needed to do.

The funny thing was, when we forced people to do the extra work of cleaning their machines, they actually started to take pride in their work area and they took better care of it.

Equipment purchases

I know it sounds like I am just trying to sell another machine, but let me tell you what happens when you install a new machine.

There is a change in the atmosphere. There is some optimism, some hope. “The boss bought me a new machine! He did realize how bad that old machine was. He does care about me.”

When a presser gets a new press, there is a change – they are glad to go to work again. They try harder. They do a better job. The effect is unmistakable. And it affects all the plant – including you! If you have never bought a new machine, you will not understand what I am taking about.

Do you care about your team? Give them a reward. Often the increase in production, savings in utilities and improvement in quality will pay for the machine.

I understand it is a lot of money. What you don’t recognize is the cost of all the additional touch-ups you are paying for right now. Maybe it costs you half an hour per day in extra touch-ups. That’s $15 per day, $75 per week or $3,900 per year. And that is just the financial cost. What does it cost you in staff frustration, customer disappointment and utilities just because your press doesn’t work as well as it should?

Training

Having good people and training them is critical in our industry. New equipment, new locations, advertising programs – all of those things are easy. Finding good people, getting them trained and keeping them motivated is huge.

Someone has said, “What happens if you train them and they leave?” The response of course is, “What happens if you don’t train them and they stay?” You need to have a place where people want to work. Then when you train them, you know they will stay.

Most often training the new person is relegated to the least qualified person in the plant. They transfer their bad habits and attitudes to the new person. Things just never improve.

We often see people doing strange things to make their machines operate. “Push this button twice. Don’t touch that. You have to process those this way.” Each time a new person is taught they get further away from the best procedures.

There are two other possibilities for training your staff. You could ask the manufacturer’s sales rep to help train your new operator. They are not always in town but most would be glad to help when they can.

Another option is to bring in a professional trainer. Someone who can spend all day helping your people do a better job. Invest in your people. They are the key to your success.

Happy well-trained people working in a comfortable place is an unbeatable combination.

One good thing that has come from Covid is cross-training. Most plants are operating with minimal staff. Those who were cross-trained and could do every job in the plant are the ones who are still working. You probably have spare time now. Use it to train your people to do multiple jobs.

Safety

The editor specifically asked me to talk about Covid. What are people doing to protect their people? That’s easy to answer – nothing!

There are very few plants that we go into where the production workers are wearing masks. We wear them to protect the people we meet, but in the back of the plant we are not seeing masks, sneeze guards or any protection. OK, maybe some sanitizer, but that’s about it. There are sneeze guards at the front counter and the counter staff wear masks, but no one else does.

If one worker comes down with Covid, you will be shut down and your people will be unable to work until the quarantine is over. Is that what you want?

Some of our suppliers have split their people into two crews. One crew works one day and the other crew works the next day. If one crew has to isolate, the other crew can carry on with production.

While we are talking about this, is your plant a safe place to work? Are the steam pipes and press heads insulated? Are all the guards in place on the machines?

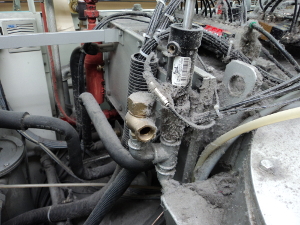

One thing that really irks me is when the covers are left off a machine. Either the mechanic is lazy or he doesn’t know what he is doing and is planning on having to come back again. Those covers are there to protect people. People sometimes get their arms caught in a machine or they get burned.

What is our attitude? That’s the way our industry is. “It’s normal to get burned. You better be more careful.” We cannot totally eliminate all danger but we can use the guards the manufacturer has provided. We can train people to be aware of danger points.

Building conditions

No one wants to work where they are uncomfortable – too hot, too cold, sweating from the humidity, unable to have a conversation over the noise, and struggling to see stains because the lighting is no good.

The pressers by the door freeze in the winter and those in the back of the plant cook in the summer. How do we get around this – we start work at 4:00 a.m. Try advertising that job!

The response from most owners is, “That’s the way our industry is. Those are the conditions that we have to put up with.” That’s not true. There are some nice plants that are very comfortable to work in.

Conclusion

Probably right now you are saying, “Nice ideas, but who is going to pay for all this?” Who pays for anything in your plant? Your customers.

If your plant is a nice place to work, the counter staff may be happier, the pressers will do a better job and customers will want to come back.

It all comes back to you. What do you want your plant to be like? What do your employees want it to be like?

EXCELLENT article. I’ve been in my share of drycleaning plant back rooms, and I’ve been left wondering: ‘How can any place so dirty produce a garment that is clean?’ C’mon folks, we are Cleaners! Shouldn’t we do for ourselves what we profess to do for others?

Great article by Mr. Marois as usual. A lot of important things to consider here. It’s tough to delegate the dirty jobs when I know it’s the last thing my staff members want to tackle, but the end result is so beneficial. Staff are happier, customers see a difference, and we take more pride in the final result when garments are picked up. If only we could keep hangers from falling behind the presses!