Don’t you hate it when you miss a news story? The very essence of “news” is that it comes and goes pretty quickly. But we want you to be able to read news after it’s been removed from our main pages. So, check this archive if you missed something.

APRIL 2025 NEWS

May Is Maytag® Month

Includes Special Financing Offer and Distributor Events

Whirlpool Corporation Commercial Laundry announced the 2025 May is Maytag® Month special financing offer. From May 1 through June 30, 2025, eligible buyers can receive 5.99% financing for up to 60 months on new Maytag Commercial Laundry washers and dryers financed through Eastern Funding.

“With decades of engineering expertise behind every washer and dryer, Maytag® Commercial Laundry equipment is designed for long-lasting performance and maximum dependability. Whether you’re upgrading a laundromat, replacing on-premises equipment, or expanding your operation, this special financing makes it easier than ever to get the durability your business needs—on terms that work for you.

“This is the perfect time for laundromat owners, on-premises operators and distributors to take advantage of trusted Maytag performance, backed by a financing offer that makes it easier than ever to invest in the future of their business,” said Amy Gardner, Director of Sales, Service and Parts, Commercial Laundry. “We’re excited to help our customers succeed and support their growth with long-lasting, dependable equipment.”

Attend a Maytag Month Open House Near You

Visit an upcoming distributor open house. Learn more about Maytag equipment, connect with experts, and get details on this limited-time financing offer in person:

Northwest Laundry Supply

Craig Moore – craigm@northwestlaundry.com or (509) 487-4800

• May 6 – Seattle, WA

• May 8 – Spokane, WA

Mendenhall Commercial Laundry Equipment

Brad Moyes – brad@mendenhallcle.com or 801-298-1133 ext: 111

• May 15 – North Salt Lake, UT

Midland Commercial Sales and Service

Don Beesley – don@midlandcommercial.com

• June 10 – Winnipeg, MB, Canada

For more information on the May is Maytag Month offer, please contact your local distributor.

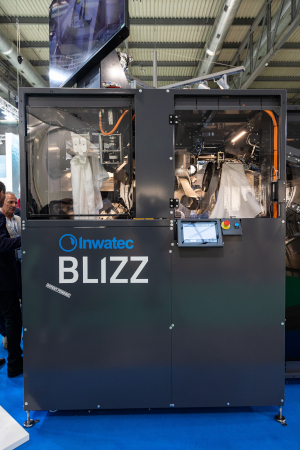

Extox Open House a “Smashing Success”

Artur Keyes-Kryaskowski and his team put together an Open House, held April 5-6, that was well-attended and a “smashing success” according to Artur.

“A huge thank you to everyone who attended our Open House! We were thrilled to showcase our premium line of dry cleaning, commercial laundry, and finishing equipment, all made possible with the fantastic support and sponsorship of our trusted manufacturers: Bowe Germany, Sankosha, Yamamoto, Seitz Gmbh, Fabritec International, AL Wilson, GreenEarth, and Seeko Pump.

The live demonstrations and our spot removal workshop were met with great enthusiasm, and it was wonderful to engage with so many of you. Your participation and interest mean the world to us! If you couldn’t make it or want to learn more about our offerings, feel free to reach out. We can’t wait to see you at our future events!”

UNX-Christeyns Transitions to Christeyns

Embracing Growth and Global Identity

UNX-Christeyns, the trusted name in commercial cleaning solutions, is excited to announce an evolution in its brand identity. Beginning in late April 2025, the company will transition its brand identity from UNX-Christeyns to Christeyns, reinforcing its place as part of the global Christeyns family of companies while continuing to operate as an independent entity (Christeyns North America), dedicated to superior service and industry leadership within the North American markets.

This name transition does not reflect a change in ownership but rather marks a natural progression in the company’s growth strategy. Since the successful merger of UNX Industries and Christeyns USA in July 2022, the organization has strategically implemented changes in phases to ensure a seamless experience for both employees and customers.

“This rebrand has been part of our long-term vision since merging in 2022,” said Josh Lilley, CEO of UNX-Christeyns. “This transition communicates a clear and unified message about our global identity, which is increasingly focused on market-leading customer partnerships, innovation, and technology.”

The UNX-Christeyns Board of Directors also shared their enthusiasm for the next phase of the company’s growth. “Our board and shareholders are thrilled about the past, present, and future success of our company in North America. While we’ve operated as the North American division of Christeyns since our merger in 2022, this shift provides clarity correlated to our position in the global market.”

As part of this transformation, UNX-Christeyns is also proud to announce plans for a state-of-the-art manufacturing facility in Greenville, NC, set to be completed by the end of 2025. This cutting-edge facility will enhance manufacturing efficiencies, increase capacity, and consolidate the company’s manufacturing, engineering, R&D laboratory, and corporate offices into one location. “This investment demonstrates our commitment to long-term growth and excellence,” added Lilley. “By increasing production capabilities and efficiency, we will be better positioned to support our customers and drive innovation within the industries we serve.”

Further details on the new facility and other strategic initiatives will be shared in the coming months.

Braun Launches Redesigned Website to Enhance Customer Experience

G. A. Braun, Inc., a leading U.S. manufacturer of industrial laundry equipment, is proud to unveil the newly redesigned gabraun.com — created to deliver a better, faster, and more customer-focused experience.

With improved navigation, a mobile-friendly design, and clearer access to both products and people, the new gabraun.com makes it easier than ever for customers to connect, explore, and choose Braun.

Key features of the redesigned gabraun.com include:

- A new, visually enhanced homepage and site layout

- Streamlined navigation across all devices

- Industry-specific laundry solutions

“The redesigned site highlights what sets Braun apart— durable, American-made

equipment backed by our people, expert support, and dependable solutions. It’s now

easier than ever for site visitors to find exactly what they need,” said Traci Anelli,

Director of Marketing.

“This is more than a website refresh — it’s part of our commitment to evolving with our

customers. Whether you’re starting a new laundry, expanding an existing operation,

ordering replacement parts, or connecting with our team, the new gabraun.com is built

to support you every step of the way.”

Experience the new site design today at www.gabraun.com.

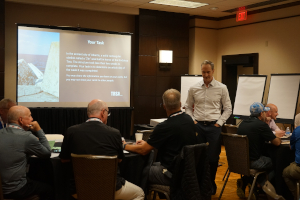

ALM’s 2025 Elevate Conference Sets New Standard for Learning and Networking

The inaugural ALM Elevate Conference, held from March 17-19, 2025, in Nashville, TN, attracted 118 professionals, including 68 laundry operators, 43% of whom were decision-makers. This two-day event offered hands-on workshops, expert insights, and valuable networking opportunities, providing attendees with practical tools to enhance their operations and industry knowledge.

“We are thrilled with the success of Elevate’s inaugural event,” said Sarah Brobeck, President and CEO of ALM. “The engagement from our attendees has been incredible, and the feedback has been overwhelmingly positive. Elevate offered a platform for professionals to expand their skills and connect with peers.”

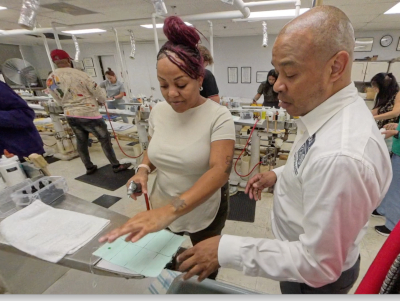

Hands-On Learning and Real-World Application

The conference kicked off with sessions on Root Cause Analysis to identify areas for operational improvement. Linen management participants took part in a beer supply chain simulation, addressing inventory and ordering challenges. Nathan Mein, General Manager, TMC Laundry Cooperative noted, “Today’s class opened my eyes to the efforts that our partner owners put into reducing overtime and plant capacity, which ultimately helps save time and money.”

Laundry operators participated in a LEGO manufacturing line exercise, learning to streamline workflows using LEAN tools. “The LEAN presentation and exercise was not only fun but particularly telling,” said Graham Skinner, RLLD, VP of Business Development & Technical Support from UNX Christeyns. “It made you physically and mentally see how to eliminate production constraints and reduce waste.”

Sessions focused on fostering collaboration. Liz Remillong, Vice President, Core Linen emphasized, “Everything we discuss today benefits the plant and operations, helping to improve both customer service and plant performance.”

Networking and Collaboration

The second day focused on applying these concepts to real-world scenarios. Dan Sanchez, President, Sanchez Advisory Group led role-playing exercises, helping linen managers gain buy-in from hospital stakeholders. On the operations side, Bob Corfield, CLLM, CEO, Laundry Design Group, facilitated a sequencing activity, encouraging operators to apply workflow management strategies. “If they can come away with just those small, low-hanging fruit improvements, it can help improve workstation ergonomics and process throughput,” said Corfield.

Networking was a key element of the conference. The Margaritaville Mixer, sponsored by Future Polytech, encouraged attendees to connect in a relaxed, fun atmosphere. “The networking is amazing… everyone is so willing to share their knowledge and experiences,” said Christine Arnold-Tun, RLLD, CLLM, Assistant Managing Director, Belize Commercial Laundry and Linens.

The event concluded with the Tropical Paradise Reception, sponsored by Positek RFID, offering a chance for attendees to continue their conversations and deepen connections.

A Memorable Experience

The Elevate Conference successfully combined expert-led learning, hands-on activities, and networking. “I think it was a great workshop, in that, you get to network with others who do your job, and also in the way that you get to take some simple take-homes that you can implement right away in your laundry facility, and your day-to-day life,” said Chip Malboeuf, Vice President, Operations and Engineering, ImageFIRST and ALM Chairman.

For more information on upcoming ALM events, visit ALM’s Website or follow ALM on social media.

CLATA Holds Annual General Meeting

The Canadian Laundry Allied Trades Association (CLATA) held it’s Annual General Meeting, and announced the Board of Directors for 2025-2026.

CLATA’s AGM was held on April 3, 2025 in Toronto, Ontario.

2025-26 Board of Directors

- Ashlynn McConvey (Dalex Canada Inc.), President

- Earl Eichen (Lavanett Equipment), Past President

- Steve Freeman (CLATA), Secretary

- Trevor Holmes (CLATA), Treasurer

- Malcolm Caldwell (Harco Co. Ltd.), Director

- Patrick Robertson (Tingue Canada), Director

- Denis Lamarre (Lavanett Equipment), Director

- Marc-Antoine Gelac (Kannegeisser Canada), Director

- William Kahan (Unipress Corp.), Director

- Artur Keyes (Extox Industries), Director

CLATA’s annual golf tournament will be held on Thursday, September 11th at the Bay of Quinte Golf Club. Registration information will be shared at a later date. We had a record turnout at the Golf Tournament in September 2024, with 48 players and 2 people walking the course for a total of 50 people. Overall a great success.

Given the current political environment, discussions are under way with the board of directors in regards to the CLATA reception at this year’s Clean Show in Orlando.

The next AGM is tentatively scheduled for March 26th, 2026 in Toronto.

Harco receives “Top Performer” recognition for UniMac

Harco was recently recognized by UniMac brand of Alliance Laundry Systems as a “Top Performer.” Phil Lapenta from Alliance presented the award to the Harco team during a recent visit to the Harco head office in Mississauga, ON.

TRSA Announces Two Industry Awards

The Textile Rental Service Association (TRSA) announced it’s two major annual awards: the Maglin-Biggie Lifetime Achievement Award and the Operator of the Year Award.

Maglin-Biggie Supplier Partner Lifetime Achievement Award: David Tingue

David Tingue, the CEO of Tingue, Brown & Co., Peachtree City, GA, has been honored with the 2025 Maglin-Biggie Supplier Partner Lifetime Achievement Award. This award is a testament to Tingue’s exceptional leadership, his significant contributions to the linen, uniform and facility services industry, and his steadfast dedication to excellence.

“I’m incredibly honored to receive the TRSA Supplier Partner Lifetime Achievement Award,” Tingue said. “I feel a bit overwhelmed by this honor, as it has me reflecting on the many individual mentors and influencers in my life. Above all is my father, Bill Tingue, who was a recipient of this award in 2003. Dad showed me that you can come out on top while acting like a gentleman. The names of past recipients are truly humbling – these are my idols, and they always will be. Thanks to all of them for setting such a great example.”

Tingue is a stalwart of the commercial laundry industry and has had many highlights throughout his career. He led Tingue in building a global presence, solidifying a versatile supply chain that has weathered financial crises and pandemics, so that Tingue’s laundry customers were never without their necessary consumables, spare parts and local service. Under his leadership. Tingue has opened and acquired businesses in Hong Kong, Canada, the Caribbean and Ireland. He is also a visionary in digitalizing Tingue’s operations – launching an e-commerce platform in 2023 that has been widely accepted and is already depended upon by hundreds of laundry operators in their chosen global markets, including more than 100 different TRSA members.

Tingue has dedicated much of his professional time to TRSA, serving on various committees (Healthcare, Marketing, Strategic Management, Strategic Planning and, his personal favorite, the Government Relations Committee), and serving a term on the Board of Directors (2002-’04). He is a graduate of TRSA’s SMI (Sales and Marketing Institute) and is a consistent TRSAPAC contributor. A constant cheerleader for TRSA programs – he has sent dozens of Tingue employees to EMI, MMI, PMI, committees and various TRSA-sponsored events.

Tingue became the fourth-generation family manager of the firm in 1992 after earning an MBA degree from Cornell University’s Johnson Graduate School of Management. He held various management positions in the Tingue division, becoming president in 2000. In January 2007, David succeeded his father, William J. Tingue, as CEO of the parent company. Under David’s leadership, the business has closed 18 acquisitions, three business divestitures and six real estate deals.

David resides in Tampa, FL, with his wife, Andrea, and their 14-year-old daughter Hayden. Their daughter Darby (27) is a marketing executive in Chicago. Son John is the fifth-generation Tingue in the family business. A regional sales manager based in Chicago, John oversees six sales reps for the company while actively influencing the company’s digital capabilities. He is married to Hannah, who is expecting the family’s first grandchild this summer.

“We recently launched a new mission statement at Tingue: Fostering a benevolent culture that drives us to be the familiar, friendly and trusted solution for our laundry partners,” Tingue said. “This Lifetime Achievement Award suggests that we are on the right path. While this award marks a significant milestone, I believe there is still more to contribute. I look forward to continuing to support and advance the industry, ensuring that the next generation can build on the strong foundation we’ve all worked so hard to establish. Thank you to my friends of the TRSA.”

Tingue will receive the award at TRSA’s 112th Annual Conference, scheduled for May 13-15 at The Grand Hyatt Indian Wells Resort & Villas in Indian Wells, CA. Registration and details can be found at www.trsa.org/annualconference.

Operator of the Year Award: Douglas “Woody” Ostrow

Douglas “Woody” Ostrow, President of CleanCare, Pittsburgh, will be honored with the TRSA Operator Lifetime Achievement Award at the 112th TRSA Annual Conference taking place May 13-15 at the Grand Hyatt Indian Wells Resort & Villas in Indian Wells, California. The award presentation will be held during a special dinner on May 15.

A third-generation leader in the industry, Ostrow has dedicated more than 50 years to the linen, uniform, and facility services industry. “My father won this award as well,” said Ostrow. “Without any false modesty, I don’t like recognition. I’d rather stay in the background. So, winning this award is a very flattering honor, and I’m proud to accept it.”

The award pays tribute to exceptional personal service to TRSA and the linen, uniform and facility services industry as nominated by past operator award peers and voted on by the TRSA Executive Committee. Winners have supported the association for decades, devoting their own time to association activities and facilitating their employees’ involvement in TRSA. Their teams have taken advantage of a wide range of TRSA activities, including certification, in-person and virtual events, and benchmarking surveys.

Ostrow has been recognized for a lifetime of service to TRSA and the industry. For TRSA, he served as chair (2010-’12), vice chair (2007-’09), treasurer (2005-’07) and a member of the Board of Directors (2004-’07) and the TRSA Executive Committee. He also served a pivotal role on the transition committee that oversaw the merger of TRSA with the Uniform and Textile Service Association (UTSA), which served the industry for 75 years and blended with TRSA in 2008. Additionally, Ostrow chaired the search committee that hired current TRSA President & CEO Joseph Ricci in March 2010.

Ostrow’s dedication to furthering the industry’s best interests has been reflected in other volunteer leadership positions, as he also chaired TRSA’s Operations Committee from 1981-’83 and served on the association’s Government Relations Committee. During his time on TRSA’s Board of Directors, Ostrow also was an active member of TRSA’s Healthcare Committee. In addition, he is a founding member of HOSLIN, a hospital linen cost and analysis trade group, and served on the MEDtegrity Executive Board.

Michael Potack, a former TRSA Lifetime Achievement Award winner who served on TRSA’s Board of Directors with Ostrow, said, “Woody was always very tuned in. He paid attention and was interested in how the industry worked and his company worked. He has provided a lifetime of service to TRSA and other industry groups, and his company has been a good citizen in his community in the Pittsburgh area.”

Ostrow and his family have a long tradition of involvement with TRSA dating back to 1934. Ostrow’s grandfather, Moe Struminger, was president of TRSA’s predecessor organization, the Linen Supply Association of America (LSAA), from 1949-’51, and Ostrow’s father, Gerald Ostrow, was president of TRSA from 1987-’89.

Ostrow joins 39 past recipients who have received the award since its 1982 inception, the most recent of whom were:

2024: Jim Buik, Roscoe Co., Chicago, IL

2023: Jim Vaudreuil, Huebsch Services, Eau Clare, WI

2022: Brian O’Neil, California Linen Services, Pasadena, CA

2020: Bob Brill, Republic Master Chefs/American Textile Maintenance, Los Angeles, CA

2019: Tom Watts, Prudential Overall Supply, Irvine, CA

2018: Steve Larson, Alsco Uniforms, Salt Lake City, UT

2017: Ronald Croatti, UniFirst Corp., Wilmington, MA

2016: Steve Bryant, Wildman Uniform & Linen, Warsaw, IN

2014: Michael Potack, Unitex Textile Rental Services, Mount Vernon, NY

2013: Richard Senior, Morgan Services, Chicago, IL

For more information and to register for the TRSA Annual Conference, visit www.trsa.org/annualconference.

MARCH 2025

EVI Industries to Acquire Girbau North America

Girbau North America (GNA), Oshkosh, WI, announced on March 3 that it is being acquired by EVI Industries Inc. (EVI), Miami. Terms of the deal were not disclosed.

GNA, formerly a subsidiary of Girbau, will conduct business as usual moving forward without changes to leadership, staff, services, support or culture, according to GNA President Mike Floyd. “We remain dedicated to our customers, and now our resource pool of products, knowledge and services has grown thanks to the many partners of EVI across the United States,” Floyd said. “Simultaneously, we continue to rely on Girbau’s expertise and leadership in manufacturing to deliver best-in-class laundry solutions.”

GNA is EVI’s 30th and largest acquisition in the commercial laundry distribution and service industry. By joining EVI Industries, GNA gains access to a growing network of laundry distributors and service providers, positioning the company for accelerated growth and expanded market reach while maintaining its role as a key partner of Girbau.

“Joining EVI Industries marks an exciting new chapter for Girbau North America,” Floyd said. “EVI’s commitment to the laundry industry aligns perfectly with our mission to provide world-class equipment and services to our customers. This partnership enhances our ability to serve the laundry industry with even greater efficiency and innovation through an expanded base of laundry solution tools and programming for all GNA customers.”

EVI Industries has rapidly expanded its presence in the laundry industry through strategic acquisitions, integrating leading distributors and service providers to create a robust, customer-focused network. The addition of GNA further strengthens EVI’s ability to offer comprehensive laundry solutions across multiple market segments.

“We are thrilled to welcome Girbau North America to the EVI family,” said President and CEO Henry Nahmad. “Girbau North Amercia’s strong brand reputation, comprehensive product offerings, dedicated team and customer-centric approach make them an ideal addition to our growing platform. Together, we will continue to set new standards in commercial and industrial laundry solutions while preserving GNA’s strong relationship with Girbau as a key manufacturing partner.”

GNA maintains its long-standing role in representing Girbau-manufactured laundry solutions, just as it has for the past 30 years. “With EVI’s competitive influence, we anticipate an accelerated pace for bringing new products from Girbau and other business partners to market,” Floyd added.

From Girbau’s perspective, this transition presents an opportunity to continue innovating and growing alongside GNA. “We are excited to continue our strong collaboration with GNA under this new structure,” said Chair and CEO of Girbau, Mercè Girbau. “For years, we have worked together to deliver industry-leading solutions, and this next chapter will enable us to drive further innovation and create even greater value for our customers.”

GNA will continue to operate under the Girbau North America name, ensuring continuity for existing customers, distributors and partners. To learn more about GNA, visit www.gnalaundry.com.

Association of Wedding Gown Specialist Gathered in Ft. Worth, TX

Members of the Association of Wedding Gown Specialists (AWGS) met recently in Fort Worth, Texas. In addition to the traditional tour of the host member’s plant, Kite’s Cleaners and Pinstripes, owned and managed by Nathan Kite, guest speakers included designer Callie Tein of Luna d’Miel Bridal, Emily Foster of Emily Foster Creative, Tracy Aaron of Wedding and Party Network, Kayla Fogarty of TheKnotWW.com, and Michael Tungesvick of Sankosha-USA.

As always, a highlight of the meeting was the presentation of the fourteenth annual Jack Barth Memorial Award of Excellence. Initiated by Linda Stokes-Barth in remembrance of her late husband and his achievements in the dry cleaning industry, the award recognizes an AWGS member for advancement, promotion, and development of industry standards for wedding gown care as well as for outstanding contributions and service to the Association and its members.

This year’s recipient, Ken Kinzer of Bridgestone Cleaners in Brooklyn, New York, began his garment-care journey more than four decades ago in 1983. In that time, Kinzer has achieved respect in the industry and pioneered eco-friendly techniques as well as taken on many leadership roles. Always a strong advocate for the industry, he has served as President of the National Cleaners Association, led community initiatives such as the Brooklyn Coats for Kids Campaign, and received numerous awards from groups such as the Clothing Care Council.

AWGS president Kyle Matthews of Janet Davis Cleaners in Berkley, Michigan, presented the Barth Award to Kinzer, who first represented AWGS in Brooklyn and then expanded into Manhattan, the Bronx, and Westchester County, New York. “Kinzer’s clients describe his work as nothing short of meticulous and masterful,” said Matthews, “and one reviewer summed it up perfectly with the comment that ‘Ken treats every gown like it’s a priceless heirloom—because to the bride, it is.’ Ken, your leadership, craftsmanship, and commitment to AWGS make you more than deserving of this honor.”

Other speakers at the event included AWGS members Nadine Rana of Style and Grace Cleaners in Toronto, Ontario, and Ben Feingold of Fabricare Center Cleaners in Atlanta, Georgia on the topic of TikTok as well as Jan Barlow of Jan’s Professional Dry Cleaners in Flint, Michigan, on best hiring and incentive practices.

In addition to speakers, there was a series of round-table conversations offering everyone in the group the chance to discuss topics ranging from “must” updates for websites to keeping mechanical employees happy. AWGS table hosts included Jan Bohn of Margaret’s Cleaners in San Diego, California, on handling luxury garments, Marissa Gonzales of Five Star Wedding Gown Specialists in San Antonio, Texas, on starting a wedding alterations department, Melisa Soonius of Kite’s Cleaners and Pinstripes in Dallas/Fort Worth, Texas, on scheduling gown pick-up and delivery, and Margaret Butler of Dublin Cleaners in Dublin, Ohio, on developing a start-up video.

Matthews presided over the installation of officers who are vice president Rana, secretary-treasurer Rhonda Wernick of Oakwood the Greener Cleaners in Nashville, Tennessee, and immediate past president Kermit Engh of Methods for Management. Malcolm MacGregor of Brown’s Cleaners in Ottawa, Ontario, is chair of the Budget and Finance Committee.

Incoming members of the Board of Directors are Feingold and Kerryn Wollington of LDC Luxury Drycleaning in Cardiff, New South Wales, Australia.

Members new to the Association are Nina Lapin and Roman Cheb of Greenacres Cleaners and Alterations in Spokane Valley, Washington, Cameron Bastien of Carousel Cleaners in West Vancouver, British Columbia, Chad McMurtrie of Pristine Dry Cleaners in Tauranga, Bay of Plenty, New Zealand, Matthew Hyde of Hyde’s Quality Drycleaners in Gisborne, Victoria, Australia, and Bill Hudson of Cressbells Dry Cleaners in Ballarat, Victoria, Australia.

Sponsors of the event were Kreussler, Inc., Foster-Stephens, Inc., Sankosha-USA, Inc, Select Risk Insurance, and Kleerwite Chemicals.

AWGS is a not-for-profit trade association with members in nine countries. Members are certified to ensure that wedding gowns and heirloom textiles of all kinds are cleaned according to established museum standards and preserved in archival-quality materials. Wedding couples benefit from the personal, interactive service offered by wedding gown specialists in local communities, but the guarantee is truly an international warranty because each member honors the guarantee of every other member no matter where in the world they may be. Also, for every gown preservation, AWGS partners with the international Arbor Day Foundation to plant a tree in celebration of the bride’s wedding in a forest of great need.

AWGS members benefit from both trademarked logos and other promotions such as wedding gown care labels and recommendations from more than 70 gown designers including Romona Keveza, Modern Trousseau, Paloma Blanca, Justin Alexander, and Enzoani.

AWGS’s MuseumCareTM preservations are also Endorsed by the Association of Bridal Consultants, the professional organization dedicated to wedding planners and professionals worldwide

For more information about training and membership, call the Association office

at 800-501-5005 or go to www.WeddingGownSpecialists.com or www.WeddingGownSpecialists.net.au.

DLI Launches Industry-Wide Social Media Campaign

DLI’s Social Media Action Committee has worked quietly behind the scenes to develop a program to benefit all drycleaners. They are encouraging professional garment care providers (members and non-members of DLI) to share a new series of social media posts, currently under development.

The posts will be designed by the committee with help from a social media consulting firm. The main goals are to educate consumers on the value and convenience of professional cleaning. Think of the famous Got Milk? campaign, but powered by social media posts instead of millions of advertising dollars.

DLI Launches Industry-Wide Social Media Campaign

DLI’s Social Media Action Committee has worked quietly behind the scenes to develop a program to benefit all drycleaners. They are encouraging professional garment care providers (members and non-members of DLI) to share a new series of social media posts, currently under development.

The posts will be designed by the committee with help from a social media consulting firm. The main goals are to educate consumers on the value and convenience of professional cleaning. Think of the famous Got Milk? campaign, but powered by social media posts instead of millions of advertising dollars.

2025 DLI Hall of Fame Nominations soon to open

The Drycleaning & Laundry Institute is getting ready to open nominations for the Hall of Fame 2025. If you submitted a nomination last year and it was not chosen, consider submitting your 2024 candidate again this year. Last year was the inaugural year for the program and DLI had an impressive list of candidates.

“The one thing I would stress is that the decision is made purely on the strength of the nomination form. The review process attempts to turn a blind eye to the name of the individual and is judged on the merits of what is written on the form,” said Mary Scalco of DLI.

Nominations will be accepted for the 2025 Hall of Fame from April 1 to May 15. Please visit DLIonline.org/HoF to access the nomination form at that time. If you have any questions please do not hesitate to reach out, mscalco@dlionline.org.

Kudos to Free Laundry Access Program for great Toronto Star coverage!

If you’ve met Nancy Seto of Yummi Cafe Laundromat, you know she’s passionate about the Free Laundry Access Program she launched in 2023, with sponsor Sunlight Detergent. And she’s a master at getting publicity for the program. If you want to see how to do public relations right, check out the full page article in the Toronto Star from earlier this week! Well done, Nancy, and congrats to Jim St. Pierre and wife Dahna Sanderson, co-owners of Wishy Washy Coin Laundry, for joining this worth-while program.

Housing is now open for the Clean Show — so jump on your reservations ASAP to ensure you get the hotel you want. The closer hotels fill up fast! For information, go to the Clean Show website

PayRange acquires laundry operating system Turns

US company PayRange – a pioneer in mobile payment solutions for unattended retail businesses – has acquired Turns, an all-in-one laundromat operating system.

The acquisition is aimed at enabling the laundromat industry to transform by creating an industry-first platform, combining the machine payment platform with Turns’ new age laundry operating system. Among other things, the system includes business management, pickup and delivery management software, point-of-sale and payments. In that respect, the industry platform will provide single-store and multi-location laundry owners with a unified solution for their entire business – from machine payments to wash-dry-fold service to pickup and delivery.

Founder of Turns, Sukanth Srivastav, states that his platform was built to redefine laundromat management and that together with PayRange they can play an important role in the future of the laundromat business. Sukanth: “The vision is clear: a platform that doesn’t just process payments but transforms laundromat operations entirely. Within the next 24 months, we aim to power more than 5,000 laundromats across the U.S. – giving owners the tools to grow, scale, and create exceptional customer experiences.”

TRSA Lays the Groundwork for Action in Canada

(From TRSA)

Due to the growing need for the linen, uniform and facility services industry to have representation in Canada, TRSA recently organized a planning meeting in Ottawa to develop a strategic approach to advocacy and define industry issues. TRSA’s Canadian Legislative Team, The Wellington Group, helped facilitate the meeting with a select government relations working group led by Randy Bartsch, TRSA chair; Joseph Ricci, president and CEO of TRSA; and Kevin Schwalb, TRSA’s vice president of government relations.

During the meeting, attendees heard from Canadian Senator Daryl Fridhandler and Mike de Jong, a former member of the British Columbia Legislative Assembly, to gain an understanding of the policy climate at both the federal and provincial levels of Canadian government.

The attendees discussed a wide array of topics impacting the industry such as tariffs, environmental concerns surrounding microplastics and PFAS, and currency exchange, to name a few. After deliberation, the group narrowed in on three specific issues in which TRSA will concentrate to help create Canadian jobs, improve supply-chain security and reduce costs and waste.

The three issues that the group agreed upon include:

- Increasing the use of reusable textiles

- Securing tax incentives that encourage reinvestment

- Reducing inter-provincial business impediments to help the business climate for the industry

“Our recent meetings in Ottawa were a defining moment for TRSA as we strengthen our advocacy for our members operating across Canada,” Bartsch said. “As the association’s first Canadian chair, I was truly inspired by the engagement and focus of our GR working group – a broad mix of TRSA members from the healthcare, industrial and hospitality sectors, which included family-owned firms, co-operatives and large multinationals, all united in serving the linen, uniform and facility service needs of Canadian businesses from coast to coast. Our clear advocacy priorities – promoting reusable textiles, pushing for tax policies that support capital reinvestment and reducing interprovincial trade barriers – lay out a bold roadmap to help our members drive job creation, enhance supply-chain resilience and build a more sustainable future for Canada.”

Ricci added that, “These issues provide a framework for TRSA’s advocacy efforts to promote, expand and protect the linen, uniform and facility services industry in Canada. The timing and scope of our efforts in Canada is especially critical given the recent developments in the United States and Canadian politics and relations.”

2025 Best Plants and 10 Other Top Awards Presented at Annual Industry Conference

TRSA member companies and their exemplary individual performers were honored by their peers Feb. 5 for their pursuits as employers, service providers, marketers and community leaders.

The ceremony at the Annual Industry Awards Dinner at TRSA’s 15th Annual Legislative Conference culminated in the presentation of Best Plants accolades to industry leading facilities for their comprehensive efforts to improve capabilities to supply, launder and maintain linens and uniforms. They cite statistical results across a wide range of indicators from environmental stewardship to productivity improvement. Winners of the highest honor (Gold level) in this category were:

NOVO Health Services, Madison (Nashville), TN – Opened in 2016, the facility underwent major refurbishment of existing equipment in 2024, upgrading two tunnel washers, presses, dryers, ironer/folder/feeders and blanket blasters. The tool room and engineering shop were renovated. About 7,000 square feet of plant space was renovated, with the finished goods end of the plant adding 900-plus feet of trolley storage for garments shipped to depots. A boiler and make up water system/tank were added. The facility produces 55,000 lbs. (24,947 kg.) daily and has 75 employees.

Unitex Healthcare Laundry Services, Lawrence, MA – The plant, opened in 2020, produces more than 160,000 lbs. (72,574 kg.) per day and has 221 employees. It scored high marks for technology upgrades, namely a 2024 transition to new business management software (route accounting). Extensive efforts to determine customer satisfaction were cited. Performance measures cover responsiveness, frequency of in-person visits, customer service, transportation and delivery, product quality and overall linen service. Each main linen item’s quality is individually rated.

The full list of award winners

Above & Beyond Service

Honoring exceptional attention to customer needs by individuals and organizations, setting a high standard for others to follow, as selected by industry peers.

GOLD

- Alliant Systems | Irving, TX

- Foltex USA | Columbia, SC

- Jim Baker | Loop Linen | Westwego, LA

SILVER

- T.J. Peterson | TJP Laundry Maintenance Solutions | Janesville, WI

HONORABLE MENTION

- Customer Service Team | LinenMaster | Vero Beach, FL

- Ed Shanks | Ecolab Textile Care | St. Paul, MN

- Marlene Frias | NOVO Health Services | Atlanta, GA

- Systems Performance Team | Kannegiesser ETECH | Minneapolis, MN

Advertising Effectiveness

- G.A. Braun | North Syracuse, NY

- Jensen USA | Panama, FL

Best Plant to The Year

Honoring achievements, surmounting obstacles and citation of statistical results across a wide range of indicators of improved capabilities, from environmental stewardship to productivity gains.

GOLD

- NOVO Health Services | Madison, TN

- Unitex Healthcare Laundry Services | Lawrence, MA

SILVER

- Alsco Uniforms | Vista, CA

- PureStar Group | Norwich, CT

HONORABLE MENTION

- UniFirst Corporation | Hammond, IN

- Wildman Business Group | Warsaw, IN

- | Englewood, CO

Clean Green Innovation

Honoring leadership in reducing environmental impact, aligned with best management practices of the TRSA Clean Green standard, as selected by industry peers.

GOLD

- HLS Linen Services | Ottawa, ON, Canada

- PureStar Group | Brady Linen | Las Vegas, NV

SILVER

- UniFirst Corporation | Wilmington, MA

HONORABLE MENTION

- Ecolab Textile Care | St. Paul, MN

- Penn Emblem | Philadelphia, PA

Company Community Service

Honoring significant contributions to communities by organizations, reflecting their care for and sense of responsibility to the public. Industry peers select winners.

GOLD

- Adrienne Dirosario | NOVO Health Services | Atlanta, GA

- Deanne Banton | Nixon Medical | New Castle, DE

- PureStar Group | Las Vegas, NV

SILVER

- Bates Troy, Inc. | Binghamton, NY

- Chad Renegar | NOVO Health Services | Rockmart, GA

HONORABLE MENTION

- A1 American | Pacoima, CA

- Cintas Corporation | Mason, OH

- UniFirst Corporation | Wilmington, MA

Diversity Recognition

Honoring leadership in valuing the uniqueness of individuals and encouraging and facilitating variation in human qualities in the workforce, as selected by industry peers.

GOLD

- Adrienne Dirosario | NOVO Health Services | Atlanta, GA

- Deanne Banton | Nixon Medical |New Castle, DE

- PureStar Group | Las Vegas, NV

SILVER

- CW Resources | New Britain, CT

HONORABLE MENTION

- HLS Linen Services | Ottawa, ON

Fleet Graphics

GOLD

- U.S. Linen & Uniform | Richland, WA

SILVER

- Arway Linen & Uniform Rentals | Philadelphia, PA

- NOVO Health Service | Simple | Atlanta, GA

HONORABLE MENTION

- UniFirst Corporation | Wilmington, MA

Member Engagement

Honoring exemplary participation in the wide range of TRSA activities that improve individual and corporate performance.

GOLD

- Dempsey Uniform & Linen Supply | Jessup, PA

- HHS-FMA Laundry | St. Paul, MN

- Alliant Systems | Irving, TX

- Jensen USA | Panama City, FL

- Pellerin Milnor | Kenner, LA

SILVER

- Miller’s Textile Services | Wapakoneta, OH

- Superior Linen Service | Tulsa, OK

- UniFirst Corporation | Wilmington, MA

SafeTRSA Excellence Award

Honoring leadership that embraces safety as a true corporate value, indicated by exceptional support from top management, plus employee involvement, training and communication. Industry peers select winners. as selected by industry peers.

GOLD

- UniFirst Corp. | Owensboro, KY

SILVER

- PureStar | Las Vegas, NV

TRSA Legislator of the Year Award

Honoring the U.S. legislator who is most supportive of the linen, uniform and facility services industry. The TRSA Government Relations Committee selects awardees.

- Rep. Danny Davis | House of Representatives (D-IL)

Best Video

Honoring creativity and messaging in video, whether purely informative (showcasing employees, products or services) or technical (describing capabilities, processes or training).

GOLD

- HLS Linen Services | Ottawa, ON

- Magic Laundry Services | Montebello, CA

- Unitex Healthcare Laundry Services | Elmsford, NY

SILVER

- American Textile Maintenance | Los Angeles, CA

- G.A. Braun | North Syracuse, NY

- ImageFIRST Healthcare Laundry Specialists | King of Prussia, PA

HONORABLE MENTION

- Republic Master Chefs | Los Angeles, CA

- Service Uniform | Englewood, CA

For the 2026 TRSA Industry Awards, members are encouraged to visit the awards pages on the TRSA website to learn more about the honors and how to nominate candidates for next year.

It’s Going to be a Great Show!

Clean Shows are always big. This week, Messe Frankfurt announced it is expanding the Show floor to accommodate more booths. So the BIG just got BIGGER.

If you haven’t made your plans yet, now is the time to think about it. Registration will open shortly, Housing will open in March. Booth space opened a few months ago. Get out your calendar, mark out August 23-26, and start planning your visit to Orlando. This is a no-brainer.

JANUARY 2025 NEWS

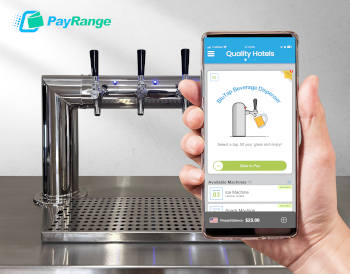

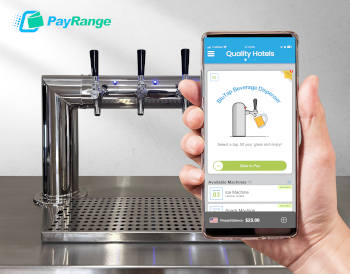

PayRange BluTap(TM) Self-Pour Technology Wins “Best Vending Solution” at the Automation & Self-Service Awards

Announced at the Self-Service Innovation Summit on December 10, 2024 in Tampa, Florida, the award honors innovators who are leading the way in the advancement of automation and self-service technologies.

PayRange, an innovator in mobile payment solutions and hardware for automated retail, announced they were awarded the “Best Vending Solution” at the annual Self-Service Innovation Summit for their patented BluTap(TM) self-pour technology solution.

By seamlessly integrating connectivity, age verification, and cashless payments, BluTap transforms traditional beverage pour bars into a streamlined and compliant self-service bar experience, all through the convenience of the user’s smartphone.

Designed with both businesses and consumers in mind, users can seamlessly verify their age one time using the PayRange age verification services, ensuring every sale is a responsible and compliant transaction. BluTap also features built-in over-consumption controls, ensuring venues and businesses can responsibly sell unattended adult beverages.

The BluTap device simply installs on beverage equipment manufacturers’ tap equipment to enable the equipment to accept both cashless payments and age-verification. BluTap utilizes the connectivity of the user’s phone along with built-in encryption protocols to eliminate the need for network access, enhancing security and minimizing risks for businesses. This makes BluTap the most advanced and scalable solution in the industry. By seamlessly integrating into both new and existing beverage equipment, PayRange offers venues the smartest and most cost-effective way to generate new revenue streams while providing unique guest experiences. BluTap eliminated the shortcomings of other self-pour technology; no RIFD cards, manual ID checks, payment terminals, POS integration or dedicated network connections required. No other self-pour technology offers the level of advanced security features of the multi-factor verification and authentication that’s built into BluTap.

“We’re honored to have been awarded the “Best Vending Solution” at the Self-Service Innovation Summit and it further validates the market response we’ve seen. BluTap has been well received in the market this year. Our first installations have been with national franchised hotel brands, and we’ve had consistent inquiries from franchisees who have heard of the system and are interested in adding it to their properties,” stated Stephanie Cordisco, Executive Vice President for PayRange. “Self-serve beer and wine dispensing is an amenity well suited to hotel properties, many of whom are still dealing with labor shortages, allowing them to reallocate their staff to other tasks while still offering their guests the convenience of self-serve beverages in a responsible manner.”

PayRange focuses on solutions that remove friction in commerce, and BluTap does just that by either seamlessly integrating with existing beverage equipment with self-pour technology or as a complete turnkey solution for a beverage program. Connected to the 24/7 PayRange advanced backend software management system, operators can make decisions based on real-time sales data, allowing them to optimize and monitor their self-pour business proactively.

Additional information is available at: https://payrange.com.

America’s Best Cleaners Partners with Retold Recycling in Support of the #NoLandfill Movement to Reduce Textile Waste

America’s Best Cleaners (ABC) announced a new and innovative partnership with Retold Recycling in support of the #NoLandFill movement to reduce textile waste and drive a more sustainable future for fashion. Launched on January 13, 2025, this collaboration will allow Retold to expand its impact by making recycling easier and more accessible through ABC’s wide network of affiliates.

The partnership between Retold and ABC is built on a shared mission: to tackle textile waste and keep it out of landfills. By combining their strengths, the two organizations are working toward a more sustainable future and are empowering consumers to make better, more eco-friendly choices.

Retold co-founder and CEO Amelia Trumble shared, “At Retold Recycling, our mission and vision for the future is #nolandfill. This is why we are so thrilled to partner with America’s Best Cleaners to be our launch partner selling Retold’s “3 Bags in a Box” in participating member’s dry cleanering stores. The nucleus for this collaboration came directly from Mark Cuban from our episode of Shark Tank when he decreed that Retold bags should be sold in dry cleaners nationwide! Thank you to ABC and your members for this step-change in educating consumers on the importance of recycling textiles and partnering with us to provide a convenient solution to divert clothing and textiles from landfills.”

As part of the collaboration, Retold is launching a new product—“Three Bags in a Box”—which contains three compostable Retold bags, neatly packaged in a giftable box. This product offers eco-conscious consumers a convenient way to recycle their textiles while also serving as a sustainable gifting option. ABC affiliates will offer Retold Recycling’s “Three Bags in a Box” product directly to their customers, increasing the availability and convenience of textile recycling.

Retold accepts a wide range of textiles, including clothing, shoes, accessories, and household items like towels and bedding. All their recycling processes occur within the United States, ensuring transparency and control over the ethical handling of materials.

America’s Best Cleaners Executive Director Chris White says, “Our partnership with Retold Recycling is an exciting opportunity for America’s Best Cleaners affiliates to take a bold step toward a truly circular textile economy. By working together and championing the #nolandfill commitment, we’re creating innovative solutions to extend the lifecycle of garments and reduce environmental impact. This collaboration underscores our dedication to sustainability and positions our affiliates as leaders in driving meaningful change in the textile care industry.”

About America’s Best Cleaners:

America’s Best Cleaners is a certification agency and an industry-leading team of consultants who assist owners, managers, and team members to realize their full potential while striving for continued personal and professional success. For more information on America’s Best Cleaners and its Affiliates, visit the webpage.

DECEMBER 2024 NEWS

DLI School Offers 10 Complete Courses for 2025

Virtual Stain Removal Now Available in Spanish

Leadership & Customer Service Virtual Courses Added

In 2025, the Drycleaning & Laundry Institute will split its virtual stain removal course into two parts, Basic Stain Removal Techniques and Advanced Stain Removal Techniques. Each course is four days long, running online Tuesdays and Thursdays over two-week periods in May, June, and July.

DLI also introduces a new Spanish language Four-Day Basic Stain Removal virtual course this November. DLI plans to expand this course into an in-person offering in the future. “Members asked for a Spanish version of our Stain Removal course,” said Brian Johnson, DLI’s Director of Education and Analysis. “We are pleased to work with Gina Hernandez, a DLI member in California to offer this course.”

DLI members most frequently cited leadership and customer service as areas of concern on a recent survey. To meet this demand, DLI partnered with Jen Whitmarsh of Snappy Drycleaning and The Route Pros to offer two new virtual courses:

- Inspire & Influence: Leadership Virtual Course

- Service Superstars: Customer Service Representative Virtual Course

DLI continues offering its best-in-the-industry in-person courses at its training facility in Laurel, MD. DLI’s school equips managers and staff at all experience levels with the latest results-driven standards, empowering confident and efficient performance.

New Leadership & Customer Service Virtual Courses

DLI introduces two new two-day virtual courses to help managers and staff quickly develop crucial skills. Both courses will be instructed by Jennifer Whitmarsh with Snappy Dry Cleaning & The Route Pros.

Service Superstars: Customer Service Rep Course – July 29 & 31

Service Superstars is a high-energy virtual course designed to transform customer service professionals into exceptional brand ambassadors. This program focuses on building the skills and mindset needed to create unforgettable customer experiences, foster loyalty, and drive success. Participants will learn effective communication techniques, problem-solving strategies, and tools to handle challenging situations with confidence and grace. Seasoned professionals or industry newcomers will gain knowledge and techniques to exceed expectations, delight customers, and shine in every interaction.

Inspire & Influence: Leadership Course – September 9 & 11

Inspire & Influence is a virtual leadership course designed to empower individuals to become impactful leaders in today’s fast-paced world. This program focuses on mastering the art of inspiration, building trust, creating a dynamic culture, and fostering individual leadership to drive success in any team.

Through interactive sessions, real-world scenarios, and actionable strategies, participants will learn how to effectively communicate a company’s overall vision, motivate others, and create a lasting positive impact. Whitmarsh and DLI designed this course to equip emerging leaders and seasoned professionals with the tools to lead with confidence, authenticity, and purpose.

Mid-West Basic Stain Removal Techniques Hybrid Course

Building on the popularity of DLI’s 2023 and 2024 West Coast Stain Removal Courses, DLI offers a special hybrid edition of its Basic Stain Removal Techniques Course in 2025. The course covers three days of virtual learning and one day of on-site training at Sankosha’s Elk Grove facility in the Chicago area.

Hybrid Basic Stain Removal Techniques

Virtual: February 20, 25 & 27

On-Site: March 5

Virtual Stain Removal Simplification & Spanish Availability

This year DLI expands its Virtual Stain Removal course into two sections: Basic Stain Removal Techniques and Advanced Stain Removal Techniques. With four-days of virtual learning each, these courses help students digest the information more efficiently and focus on fundamentals and more involved stain removal processes.

DLI will offer the Basic Stain Removal Techniques Virtual course twice in English and one session of its new Advanced Stain Removal Techniques Virtual Course in 2025. In addition, DLI presents Basic Stain Removal Techniques in Spanish in 2025. Gina Hernandez with Ortega Cleaners, a DLI Professional Member in San Juan Capistrano, CA will serve as instructor for this course.

Basic Stain Removal Techniques Virtual Course

May 6, 8, 13 & 15 (English)

July 8, 10, 15 & 17 (English)

November 11, 13, 18 & 20 (Spanish)

Advanced Stain Removal Techniques Virtual Course

June 10, 13, 17 & 19

On-Site Courses

DLI continues to offer its signature traditional in-person One-Week Introduction to Drycleaning and Two-Week Advanced Drycleaning courses twice in 2025. These courses are designed to teach students drycleaning principles and procedures that maximize quality and efficiency.

DLI’s On-Site Introduction to Drycleaning and On-Site Advanced Drycleaning courses run consecutively over a three-week period. Students who combine both courses receive a discounted rate.

On-Site One-Week Introduction to Drycleaning Course

DLI’s On-Site Introduction to Drycleaning Course is suited for experienced individuals or those who are new to the industry. It will run Monday through Friday from 9 a.m. to 4:30 p.m. at DLI’s School of Drycleaning Technology in Laurel, MD.

Some of the topics the one-week course explores include:

- sorting loads for drycleaning

- drycleaning science

- fibers and their characteristics

- fabric construction

- cleaning silk, satin and other fabrics

- soil and cleaning theory

- operating a drycleaning machine

- stain removal chemistry and procedures including removing ink, coffee, grease and other stains from clothing

- pressing pants, coats and skirts

- using tensioning equipment to improve finishing quality

- and more.

Tuition for DLI’s One-Week On-Site Introduction to Drycleaning Course is $2,165 for non-members. DLI members receive discounts ranging from 60% off to absolutely free depending on membership level.

On-Site Two-Week Advanced Drycleaning Course

DLI’s On-Site Advanced Drycleaning Course runs immediately after the On-Site Introduction to Drycleaning course.

The ten-day course is suited for those who have finished the introductory course or who have hands-on production experience and knowledge of basic stain removal and finishing techniques.

Course topics include:

- designing a cleaning plant with the most effective work flow

- pressing laundered shirts

- understanding the differences between solvents including perc, GreenEarth and hydrocarbon

- getting clean, white laundry

- cleaning and preserving wedding gowns

- current regulations facing the industry

- customer service techniques for cleaners

- using bleaches without damaging fabric color

- and more.

Tuition for DLI’s On-Site Advanced Drycleaning Course is $2,665 for non-members. DLI members receive discounts ranging from 67% off to absolutely free depending on membership level.

Spring 2025

387th One-Week Introduction to Drycleaning Course

March 24 – 28

387th Two-Week Advanced Drycleaning Course

March 31 – April 11

Fall 2024

388th On-Site Introduction to Drycleaning Course

October 6 – 10

388th On-Site Advanced Drycleaning Course

October 13 – 24

On-Site Complete Drycleaning Course

Students taking DLI’s On-Site Introduction to Drycleaning and On-Site Advanced Drycleaning Courses together enjoy a reduced tuition rate of $2,965 per student for non-members. DLI members receive discounts ranging from 20% off to free depending on membership level.

Complete Course information is available at DLIonline.org/Education

For more information or to register for any of DLI’s courses, contact DLI at (800) 638-2627 or visit www.DLIonline.org.

Thinking of attending? The Tom Kimmel Canadian Scholarship applies to any DLI class. Check the details on our Scholarship Page.

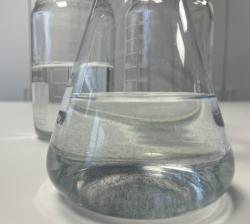

EPA bans Perc, TCE in final ruling

WASHINGTON – Today, Dec. 9, the U.S. Environmental Protection Agency (EPA) finalized the latest risk management rules for trichloroethylene (TCE) and perchloroethylene (PCE) under the bipartisan 2016 Toxic Substances Control Act (TSCA) amendments, marking another major milestone for chemical safety after decades of inadequate protections and serious delays. These protections align with President Biden’s Cancer Moonshot, a whole-of-government approach to end cancer as we know it.

TCE is an extremely toxic chemical known to cause liver cancer, kidney cancer, and non-Hodgkin’s lymphoma. TCE also causes damage to the central nervous system, liver, kidneys, immune system, reproductive organs, and fetal heart defects. These risks are present even at very small concentrations. Under today’s rule, all uses of TCE will be banned over time (with the vast majority of identified risks eliminated within one year), and safer alternatives are readily available for the majority of uses.

PCE is known to cause liver, kidney, brain and testicular cancer, as well as damage to the kidney, liver and immune system, neurotoxicity, and reproductive toxicity. Today’s final rule will better protect people from these risks by banning manufacture, processing and distribution in commerce of PCE for all consumer uses and many commercial uses, while allowing some workplace uses to continue only where robust workplace controls can be implemented.

“It’s simply unacceptable to continue to allow cancer-causing chemicals to be used for things like glue, dry cleaning or stain removers when safer alternatives exist,” said Assistant Administrator for the Office of Chemical Safety and Pollution Prevention Michal Freedhoff. “These rules are grounded in the best-available science that demonstrates the harmful impacts of PCE and TCE. EPA continues to deliver on actions that protect people, including workers and children, under the nation’s premier bipartisan chemical safety law.”

PCE and TCE are both nonflammable chlorinated solvents that are volatile organic compounds. PCE can biodegrade into TCE, and PCE may contain trace amounts of TCE as an impurity or a contaminant. The chemicals can often serve as alternatives for each other. For several uses of TCE that will be totally prohibited, there is an analogous use of PCE that can continue safely in perpetuity under workplace controls. Some examples of uses that will be prohibited under the TCE rule, but will continue under the PCE rule include: industrial and commercial use as an energized electrical cleaner, in laboratory use for asphalt testing and recovery, use to make refrigerants and other chemicals, and for vapor degreasing.

“Over 40 years ago, a mother named Anne Anderson from Woburn, Massachusetts, approached me and started a crusade to keep any more children like Jimmy Anderson, her son, from dying from cancer caused by toxic chemicals. Anne’s work directly led to this announcement from the Environmental Protection Agency that I am overjoyed to celebrate today alongside her and every community that stands to benefit—a finalized ban on trichloroethylene and most uses of perchloroethylene, two chemicals that cause cancer, affect reproductive systems, are neurotoxic, and compromise immune systems,” said Senator Ed Markey (D-MA). “Despite their dangers, these chemicals could still be found in industries like dry cleaning, automotive repair and manufacturing. With no doubt that these chemicals are deadly, there is no doubt that this final rule will save lives—especially our children’s lives—around the country.”

“The Camp Lejeune contaminated drinking water issue has dragged on over the better part of forty years ever since TCE, PCE and other organic solvents were first documented in the base’s drinking water supply in October 1980,” said Jerry M. Ensminger, Retired U.S. Marine Corps Master Sergeant. “My daughter, Janey, was conceived aboard Camp Lejeune during the drinking water contamination and died of leukemia in 1985, at the age of nine. I first began my fight for justice in 1997, and was later joined by Mike Partain in 2007, who was also conceived aboard the base and diagnosed with male breast cancer at the age of 39. Mike and I welcome this ban on TCE by the EPA and this is proof that our fight for justice at Camp Lejeune was not in vain.”

Trichloroethylene

TCE is used as a solvent in consumer and commercial products such as cleaning and furniture care products, degreasers, brake cleaners, sealants, lubricants, adhesives, paints and coatings, arts and crafts spray coatings, and is also used in the manufacture of some refrigerants. Safer alternatives are readily available for the majority of these uses.

EPA is finalizing its prohibition on all uses of TCE, most of which will be prohibited within one year, including TCE manufacture and processing for most commercial and all consumer products. This will protect most people who are likely to be exposed to TCE from uses covered by TSCA, including all consumers and workers in many sectors and many communities.

A limited number of uses in the workplace will be phased out over a longer period. Those uses will only continue with required stringent worker protections in place. All TCE uses with longer phaseout timeframes will have worker safety requirements, such as a Workplace Chemical Protection Plan that includes an inhalation exposure limit. The final rule sets a different inhalation exposure limit for airborne TCE than was proposed. This change was made in response to public comments to ensure the limit is feasible to implement and monitor while still reducing risk. EPA estimates that the new inhalation exposure limit would reduce long-term workplace exposure by 97%.

Many of the TCE uses that are continuing for longer than one year occur in highly industrialized settings that can adopt EPA’s new stringent worker protections, such as uses of TCE to clean parts used in aircraft and medical devices, to manufacture battery separators, to manufacture refrigerants, as well as in other transportation, security and defense systems.

For the use of TCE in manufacturing refrigerants, the longer timeframe supports fighting climate change by complementing efforts to phase down climate-damaging hydrofluorocarbons under the bipartisan American Innovation and Manufacturing Act.

All of these uses ultimately will be prohibited, but some of the exemptions associated with longer timeframes are necessary to avoid impacts to national security or critical infrastructure. In addition, some of the timeframes have been adjusted from the proposed rule based on public comment to allow reasonable time for transitioning to alternatives.

Further, to support cleanup activities at sites of past TCE contamination (e.g., Superfund sites), EPA is allowing essential laboratory use and proper disposal of TCE wastewater to continue for 50 years provided worker protections are in place, including the inhalation exposure limit set by today’s rule.

Learn more about the TCE rule.

Perchloroethylene

PCE is a solvent that is widely used for consumer uses such as brake cleaners and adhesives, in commercial applications such as dry cleaning, and in many industrial settings. Safer alternatives are readily available for the majority of these uses.

EPA is finalizing a 10-year phaseout for the use of PCE in dry cleaning to eliminate the risk to people who work or spend considerable time at dry cleaning facilities. Use of PCE in newly acquired dry-cleaning machines will be prohibited after six months. Compliance dates for machines that are already owned will vary depending on the type of the dry-cleaning machine used, with older types of machines being phased out sooner than newer ones. Many dry cleaners have already begun this transition. This timeline is unchanged from the proposed rule.

EPA’s final risk management rule requires companies to rapidly phase down manufacturing, processing and distribution of PCE for all consumer use and many uses at industrial and commercial workplaces, most of which will be fully phased out in less than three years. For most of the uses of PCE that EPA is prohibiting, EPA’s analysis found that alternative products with similar costs and efficacy to PCE are reasonably available.

The rule also finalizes stringent, achievable controls for continuing uses under a Workplace Chemical Protection Program. These rules generally occur in highly sophisticated workplaces that may be important to national security, aviation and other critical infrastructure, as well as uses that complement the agency’s efforts to combat the climate crisis. These uses include:

- Use in the production of other chemicals, including refrigerant chemicals that may complement efforts to phase down climate-damaging hydrofluorocarbons under the bipartisan American Innovation and Manufacturing Act.

- Use in petrochemical manufacturing.

- Use in agricultural chemical manufacturing (originally proposed to be prohibited).

- Use for cold cleaning of tanker vessels (originally proposed to be prohibited).

- Use as maskant for chemical milling.

- Use as a vapor degreasing solvent.

- Use in adhesives and sealants.

- Use in energized electrical cleaning (originally proposed to be prohibited).

- Processing into formulation, mixture or reaction products.

- Import, recycling, disposal, processing by repackaging and domestic manufacturing of PCE.

In response to public comments on the proposed rule, most workplaces now have 30 months instead of 12 months to fully implement the Workplace Chemical Protection Program. EPA also revised several other aspects from the proposal to strengthen and clarify aspects of the Workplace Chemical Protection Program, including monitoring requirements. EPA also ensured the employees’ designated representatives, such as labor union representatives, have access to occupational exposure monitoring and records.

Learn more about the PCE rule.

Additional Information

As a follow-up to consultations with small businesses, EPA plans to release compliance guidance for the use of PCE in dry cleaning and energized electrical cleaning in the coming months, as well as for the TCE rule. President Biden’s Fiscal Year 2025 budget requested funding to support small business efforts to transition to TSCA-compliant practices and mitigate economic impacts. If implemented, these grants could be used to support small businesses like dry cleaners in their transition away from PCE.

EPA will host a public webinar to explain what is in the PCE final rule and how it will be implemented on Wednesday, Jan. 15, 2025, at 12:30 p.m. EST. Registration is available on the Final Regulation of Perchloroethylene under TSCA webinar page.

ABS Laundry Business Solutions Announces Leadership Transition

ABS Laundry Business Solutions, a part of Vitec Software Group, has announced a change in its leadership. Gerard van de Donk, the current Chief Executive Officer, will step down from his role effective January 1, 2025. Marien van Bezooijen has been appointed as the new CEO.

Gerard van de Donk, who became part of ABS in 1991, has played a pivotal role in guiding the company’s growth and accomplishing significant milestones over the years.

“It has been an honor to work with such a dedicated team and to see the company evolve. I am incredibly proud of what we’ve accomplished,” says van de Donk. “This transition is part of a thoughtful and deliberate succession plan. I am confident that Marien van Bezooijen, with his extensive experience and vision, will guide ABS to continued success.”

Van Bezooijen, who serves as the Chief Commercial Officer at ABS, brings a wealth of expertise and a strong background developed through years of dedication within the industry and organization. He has been recognized for his alignment with the company’s values and long-term goals. Van Bezooijen is committed to advancing the work of delivering high standards of service and innovation that ABS is known for.

“We have a talented Management Team and dedicated employees, and I am thrilled to lead ABS as we work closely together to achieve our objectives.” says van Bezooijen. “Together, we will continue to innovate, embrace change to remain competitive and uphold the high level of quality that our customers expect. I look forward to building on the strong foundation laid by Gerard and driving the company towards new heights.”

Gerard van de Donk will remain with the company as a Senior Advisor to ensure a smooth transition. He expresses his commitment to supporting the company’s mission and future endeavors.

“I look forward to watching ABS grow under Marien’s leadership,” he concludes.

About ABS

ABS Laundry Business Solutions, founded in 1987, specializes in providing innovative software solutions for the textile care and laundry industry. With over 750 installations worldwide and a dedicated team of 175 employees strategically located to provide local support, ABS delivers advanced technology, including its ABSSolute ERP software, to streamline laundry operations, boost efficiency, and enhance service quality. Serving a global client base, ABS offers tailored solutions for businesses of all sizes, from owner operated laundries to multinational organizations. As part of the Vitec Software Group, ABS benefits from the resources and expertise of the larger organization, ensuring continued industry leadership and innovation. For more information, visit www.abslbs.com.

JANUARY 2025 NEWS

PayRange BluTap(TM) Self-Pour Technology Wins “Best Vending Solution” at the Automation & Self-Service Awards

Announced at the Self-Service Innovation Summit on December 10, 2024 in Tampa, Florida, the award honors innovators who are leading the way in the advancement of automation and self-service technologies.

PayRange, an innovator in mobile payment solutions and hardware for automated retail, announced they were awarded the “Best Vending Solution” at the annual Self-Service Innovation Summit for their patented BluTap(TM) self-pour technology solution.

By seamlessly integrating connectivity, age verification, and cashless payments, BluTap transforms traditional beverage pour bars into a streamlined and compliant self-service bar experience, all through the convenience of the user’s smartphone.

Designed with both businesses and consumers in mind, users can seamlessly verify their age one time using the PayRange age verification services, ensuring every sale is a responsible and compliant transaction. BluTap also features built-in over-consumption controls, ensuring venues and businesses can responsibly sell unattended adult beverages.

The BluTap device simply installs on beverage equipment manufacturers’ tap equipment to enable the equipment to accept both cashless payments and age-verification. BluTap utilizes the connectivity of the user’s phone along with built-in encryption protocols to eliminate the need for network access, enhancing security and minimizing risks for businesses. This makes BluTap the most advanced and scalable solution in the industry. By seamlessly integrating into both new and existing beverage equipment, PayRange offers venues the smartest and most cost-effective way to generate new revenue streams while providing unique guest experiences. BluTap eliminated the shortcomings of other self-pour technology; no RIFD cards, manual ID checks, payment terminals, POS integration or dedicated network connections required. No other self-pour technology offers the level of advanced security features of the multi-factor verification and authentication that’s built into BluTap.

“We’re honored to have been awarded the “Best Vending Solution” at the Self-Service Innovation Summit and it further validates the market response we’ve seen. BluTap has been well received in the market this year. Our first installations have been with national franchised hotel brands, and we’ve had consistent inquiries from franchisees who have heard of the system and are interested in adding it to their properties,” stated Stephanie Cordisco, Executive Vice President for PayRange. “Self-serve beer and wine dispensing is an amenity well suited to hotel properties, many of whom are still dealing with labor shortages, allowing them to reallocate their staff to other tasks while still offering their guests the convenience of self-serve beverages in a responsible manner.”

PayRange focuses on solutions that remove friction in commerce, and BluTap does just that by either seamlessly integrating with existing beverage equipment with self-pour technology or as a complete turnkey solution for a beverage program. Connected to the 24/7 PayRange advanced backend software management system, operators can make decisions based on real-time sales data, allowing them to optimize and monitor their self-pour business proactively.

Additional information is available at: https://payrange.com.

America’s Best Cleaners Partners with Retold Recycling in Support of the #NoLandfill Movement to Reduce Textile Waste

America’s Best Cleaners (ABC) announced a new and innovative partnership with Retold Recycling in support of the #NoLandFill movement to reduce textile waste and drive a more sustainable future for fashion. Launched on January 13, 2025, this collaboration will allow Retold to expand its impact by making recycling easier and more accessible through ABC’s wide network of affiliates.

The partnership between Retold and ABC is built on a shared mission: to tackle textile waste and keep it out of landfills. By combining their strengths, the two organizations are working toward a more sustainable future and are empowering consumers to make better, more eco-friendly choices.

Retold co-founder and CEO Amelia Trumble shared, “At Retold Recycling, our mission and vision for the future is #nolandfill. This is why we are so thrilled to partner with America’s Best Cleaners to be our launch partner selling Retold’s “3 Bags in a Box” in participating member’s dry cleanering stores. The nucleus for this collaboration came directly from Mark Cuban from our episode of Shark Tank when he decreed that Retold bags should be sold in dry cleaners nationwide! Thank you to ABC and your members for this step-change in educating consumers on the importance of recycling textiles and partnering with us to provide a convenient solution to divert clothing and textiles from landfills.”

As part of the collaboration, Retold is launching a new product—“Three Bags in a Box”—which contains three compostable Retold bags, neatly packaged in a giftable box. This product offers eco-conscious consumers a convenient way to recycle their textiles while also serving as a sustainable gifting option. ABC affiliates will offer Retold Recycling’s “Three Bags in a Box” product directly to their customers, increasing the availability and convenience of textile recycling.

Retold accepts a wide range of textiles, including clothing, shoes, accessories, and household items like towels and bedding. All their recycling processes occur within the United States, ensuring transparency and control over the ethical handling of materials.

America’s Best Cleaners Executive Director Chris White says, “Our partnership with Retold Recycling is an exciting opportunity for America’s Best Cleaners affiliates to take a bold step toward a truly circular textile economy. By working together and championing the #nolandfill commitment, we’re creating innovative solutions to extend the lifecycle of garments and reduce environmental impact. This collaboration underscores our dedication to sustainability and positions our affiliates as leaders in driving meaningful change in the textile care industry.”

About America’s Best Cleaners:

America’s Best Cleaners is a certification agency and an industry-leading team of consultants who assist owners, managers, and team members to realize their full potential while striving for continued personal and professional success. For more information on America’s Best Cleaners and its Affiliates, visit the webpage.

DECEMBER 2024 NEWS

DLI School Offers 10 Complete Courses for 2025

Virtual Stain Removal Now Available in Spanish

Leadership & Customer Service Virtual Courses Added

In 2025, the Drycleaning & Laundry Institute will split its virtual stain removal course into two parts, Basic Stain Removal Techniques and Advanced Stain Removal Techniques. Each course is four days long, running online Tuesdays and Thursdays over two-week periods in May, June, and July.