Afraid? Not!

Many people are afraid of their machines. “I can’t blow the boiler down,” they say. “I’m scared to go in there. It’s so noisy and I might burn myself.”

Maybe ‘afraid’ is too strong a word; let’s try ‘concerned’. Most people are scared that they might wreck something. Or they might be afraid of showing their ignorance. Or afraid that it’s going to cost a lot of money if they do something wrong or ask the wrong question.

You may be laughing at the above comments but I assure you they are real. You may not be afraid of your machines, but are you taking care of them? Whether you are afraid of your machines or you just ignore them, the result is the same: machines that don’t work properly.

When you were afraid of the monster under the bed, you defeated him by turning on the light and taking a good look. How do you defeat the monster in the boiler room? Turn on the light and face the noise and heat. You can do this.

Get help

If you don’t know how to start a maintenance program, talk to your technician or to the manufacturer. Most technicians will be glad to spend some time explaining the maintenance things that you need to do.

Most manufacturers are more than glad to help you. They might even send their sales rep out for a visit. They will explain the things you need to do to keep your machine in top shape. They want their machine to work the best it possibly can, so that you will be happy operating and owning it.

A good source of information is the manual. It will explain how the machine works and what maintenance is required. They all have lists and schedules of things to do. These are things that will save you money in the long run.

What to do

If you are hesitant about equipment, you are not alone. Many people don’t know how to take care of their machinery. They don’t know the name of the parts or how they work.

To get started, focus on just a couple of machines. Don’t try to do the whole plant at once. I’d suggest the dry cleaning machine and the shirt unit. They generally need more maintenance and are more critical to your operation.

Do you take your car in for the scheduled maintenance? Your dry cleaning machine may well be more expensive than your car, and it actually makes you money when you take care of it. It seems more than smart to keep it running well.

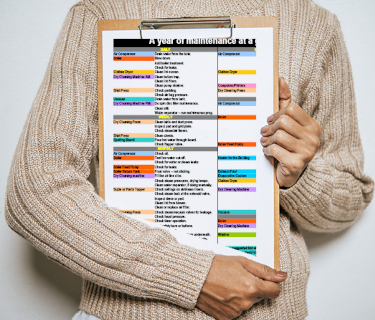

You can get software programs that track maintenance for you. Or you can use a clipboard. That works just as well, and you don’t have to turn on a computer or other device to access it. Start by reading through the maintenance section in your manual.

There are things that your operators need to do every day. There are things that need to be done weekly, monthly and even yearly. You don’t have to do all those things yourself, but you need to make sure they are being done. Awareness is the first step in making sure it is done properly and regularly.

Spend a few minutes and watch and listen to the machine. That is all we do when we come to repair things – and then we charge you for our time. On the dry cleaning machine, check solvent levels, detergent injection and look at the cleaning results. How do the clothes smell and feel? Is there static?

You can change the oil in your vacuum pump for $100 when it is scheduled to be done – or you can change the pump because it ran out of oil for $3,000. You pick.

Why bother

What are the possible outcomes if your machine isn’t working properly? You may have to reprocess the garment or spend extra time finishing it. You may damage a garment. Either way you are spending money. Wages and replaced garments are expensive.

Often the change in quality is gradual. The padding wears out and you spend a little more time doing touch-ups. It’s just a few at the beginning. You don’t notice the problem and you certainly don’t notice a little extra cost. As time goes by, things get worse. Soon you are touching up almost every shirt. But you still don’t notice, because it has been like that for so long you don’t remember how it should operate. The cost of padding will be less than the extra dollars you are paying in wages.

There is another cost when your equipment doesn’t work properly. Staff get frustrated. They think, “The boss doesn’t care so why should I?” They do the best they can with the equipment the way it is, but your quality starts to slip. “He doesn’t care about my machine so why should I care about his clothes?” Maintenance costs money – but not a much as unhappy staff.

Fresh Start

Make 2023 the year that you take control of the machines. It’s a resolution that will save you money. Start your maintenance program small, and then grow it as you succeed. Not only will your quality improve and the staff feel appreciated, but you will gain a sense of pride in your plant that you’ve never had before. And it will show.

Kevin Marois founded Calgary-based Integrity Mechanical in 2003 to service plants in western Canada. He writes on issues related to equipment, its purchase, maintenance and use. You can reach Kevin at office@imicanada.ca or via his website www.imicanada.ca