The Most Ignored Equipment

By Kevin Marois

You all have washers and dryers, whether for household laundry, wet cleaning, wash-and-fold or commercial laundry.

Washers and, especially, dryers are some of the most trouble-free machines in a plant. Because of that, they are also the most ignored. They don’t give a lot of trouble, so people don’t pay much attention to them. Not unless there is a puddle on the floor or smoke coming out the back of the dryer.

Inspect monthly

Click here for a downloadable list that we use for inspecting washers and dryers. You could check most of these things in just a few minutes per machine. You should also vacuum the lint out of the dryers once a month. Most people keep the lint filter clean, but they never vacuum around the burners and temperature sensors. It doesn’t take long. You could train anyone to do these items and report back to you.

Washer inspection points

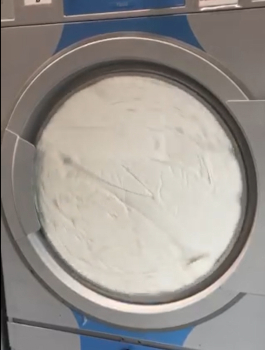

There are a few things on your washer that you should inspect every month. The fill and drain valves are most critical. Fill valves will fail to open or fail to close. When they don’t open, you may not get the proper water level or the proper temperature. When they don’t close, there will be water running down the drain even when the machine is not in use. If the valve leaks badly enough, you may get an overfill alarm. Excessively high water levels dilute your detergent and reduce mechanical action.

Most machines now have a test program or a manual function that you can use to turn the valves on and off to see if they are working properly. You can also listen inside the drum for water running or look at the drain pipe. If the washer is off, there should not be water running down the drain.

When a drain valve fails, you may get an alarm saying the water did not drain out. Or if the valve doesn’t close all the way, you may see water running down the drain during the wash cycle. This is not hard to inspect – just take the time to have a look.

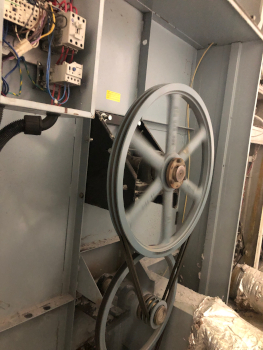

Every few months you should lubricate the washer and inspect or tighten the belt. I would also suggest that you run an empty cycle so you can check water levels and temperatures. If you are adding powdered detergent through the hopper, you need to confirm that the flush down is working. Sometimes the hopper gets plugged up with caked-on detergent.

Dryer inspection points

There are not a lot of moving parts to a dryer. There are a couple of belts or a chain and the blower fan. The biggest issue is lint. You must clean the lint screen at least daily. Air flow is critical to fast, efficient drying. Clean the lint screen and you will reduce your drying times significantly.

Once a month, vacuum out the area behind the lint screen and the area around the burners. Lint is a fantastic fire starter. Light a piece on fire and you will get more serious about cleaning your dryers.

On your monthly inspection, you should also check that the temperature is not too hot, and check the blower fan for a lint buildup. Ask your technician to show you the sail switch and you could check that it is functioning properly. It is a part of the safety circuit. It protects your plant from burning to the ground, so don’t mess with it. Some dryers also need some lubrication.

Detergent is important, too

The other thing you need to check monthly (or even weekly) is your detergent pails and pumps. The pails need to be changed regularly, and the pumps should be serviced every few months. Every plant has different workloads, so you need to be aware of your consumption and monitor when the pails should be changed.

Detergent is especially critical if you are wet cleaning. If you don’t have detergent in a laundry load, you have a dirty load that needs to be rewashed. If you don’t get detergent and texturizing in wet cleaning, you are buying some garments.

While we are talking about detergents, what else are you putting down the drain? POG (paint, oil and grease) removers? Products designed for use in dry cleaning?

Just ask your supplier, “Is this safe to go down the drain?” I have seen a hole that was melted in an ABS pipe by a dry side solvent. Fortunately the damage was not under the concrete floor.

There can also be the issue of pollution/contamination if you are not using laundry safe products. There are many effective products available that are quite safe to use in laundry. Just make sure you are using the right ones.

Safety

There are some safety concerns with washers and dryers. The covers must be reinstalled for safety. Back panels add some rigidity to the washer frame, so they are a critical part of the machine. Do not overload your machines. We recently had to fix a washer door lock on a washer. The washer was so overloaded that they broke the door trying to jam it closed. Last week I saw a fellow using a rake to pull laundry out of an overloaded washer.

Check the door switches on your dryers and washers. If the door on the dryer doesn’t close tight, you will have poor drying and could cause a fire. If the door on your washer doesn’t lock tight, someone could be injured. There have been many people injured and even some fatalities from people reaching into a spinning washer.

Dryers should never be left running at night. There have been countless cases of linen catching fire after the plant has closed. The hot linen sits in the hot steel basket and eventually catches fire. The worst culprit is spa towels with massage oils on them. Unload the dryers before you go home and let the load cool off.

Be professional; be smart

We all uses washers and dryers. Let’s do it safely and efficiently. Injuries and fires can be avoided if we are diligent.

Kevin and Paula Marois founded Calgary-based Integrity Mechanical in 2003 to service plants in western Canada. Kevin writes on issues related to equipment, its purchase, maintenance and use. You can reach Kevin at office@imicanada.ca or via his website www.imicanada.ca