Nuts and Bolts of a Strategic Mechanical Plan

Let me see your maintenance schedule and equipment replacement plan. It’s OK, I’ll wait while you find it…

What do you mean you don’t have one? Who is in charge over there? Surely someone must have a plan.

Often I hear, “Why bother to plan? I wait till something blows up. Then we’ll fix it or just replace it.”

This month’s focus is on strategic planning. Everyone believes in it – they just don’t do anything about it. Let me see if I can make some suggestions to make it easier.

Maintenance plan

Do you actually have a plan to do scheduled maintenance? Or are you like most dry cleaners – you ignore things until the machine totally refuses to work.

When you schedule maintenance, you can do it on your schedule and probably at a lower cost. You are going to pay for that part regardless. The only questions are when will it get done, how much will it interrupt your business, and how much will it cost?

You need to inspect your padding monthly. You should check the detergent pails once a week and look at the detergent pumps. Listen to the steam and vacuum valves on your presses. Look at the solvent tanks and the water separators on your cleaning machine.

Listen for steam or air leaks throughout the plant. Check the boiler gaskets. You don’t have to fix all these things, but you should be able to observe whether there is a problem.

Replacement plan

Machines are much better these days, but they still do not last forever.

It is possible to just keep fixing things – but at what cost? Also, if you stick with old equipment you don’t get the new features. (How old is your cell phone?) There are features now that can save labour. Why are you still using an old Cissell Suzie when you could have a tensioning form finisher?

Yes, money is tight, but if you don’t make a plan and start saving now you will never get ahead.

Just because you have planned to replace a press in two years doesn’t mean you have to replace it. But it does mean that you will be saving, you will be looking at replacement models, and you will be ready. But if things change and you don’t have to replace the machine you are still OK. You may choose to delay things for another year.

An important part of your replacement plan is doing research. What solvents are available? What are the latest features on shirt units? Do those gizmos actually work? Is that something that we could use? And will it save us money?

I know you could probably pay for the machine, but will it pay for itself? Will it save enough in labour or supplies to justify its cost?

Take a critical look at your equipment and decide which are the next four pieces you will replace. Then make a guess at how long they will last, and make a plan so that you will be ready when the time comes.

Training plan

Your pressers and cleaners need regular training. There are always new things to learn. New fabrics, stains, garments, machines, and even new customers with special requests. These things may require a change in your regular procedures.

People may develop bad habits over time.

Have the manufacturer’s sales rep come and do some follow-up training. They would love to do that for you. They want their machine running the best it possibly can. (Right now, of course, they aren’t travelling, but there’s always the potential for Zoom-style meetings, which are faster and more efficient.)

You would be amazed at the things we see done in plants. Somebody said, “The last owner said that I had to do this.” They have no understanding of what they are doing but they do it every day. If they’d only follow the real directions as faithfully.

Information please or ‘Just the facts, Ma’am’

We have talked about these plans for your future. But there is actually a step that comes before that.

This has been an exceptionally uncertain year, so all bets are off on productivity. Yet as things recover, it’ll be tempting to think you are busier than last year. The pressers are working much later. There is always work piled up. The loads are lined up in front of the washers and dry cleaning machines. Are you really busier or have your pressers just slowed down?

Your memory is not very accurate. How do the piece counts from this year compare to last year? Do you even have a log of piece counts from last year?

We need facts, not warm fuzzy feelings. How many pounds are you processing in laundry and dry cleaning? How many shirts did you press this week?

The key to good planning is accurate information.

Poundage charts

It’s not difficult to track the number of pounds of cleaning you are doing. This will tell you how much work you are producing.

You can click the image to download the Poundage Chart supplied by Kreussler Chemical.

List the load weights under each day. At the end of the week you can total up the days and the week. Enter those numbers into a spreadsheet and you can compare them to previous years.

You can keep the same poundage records for a washer (or washers).

No excuses. If you don’t have old figures to compare to, now is the time to start accumulating them. You’ll be in a much better position down the road.

Solvent consumption

To track your solvent consumption, record the total amount of solvent available at the beginning of the week. Add any purchases to get a total of solvent available.

Deduct the amount of solvent available at the end of the period and you will have the quantity of solvent used.

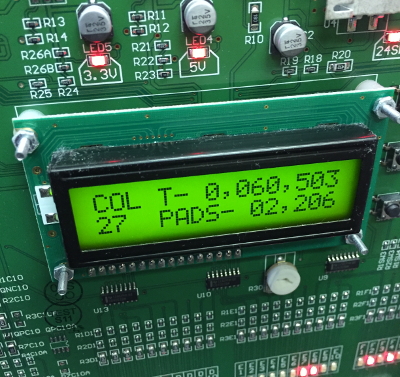

It is not difficult to figure out how much solvent is available in the machine. First thing Monday morning, before you turn the machine on, write down the amount of solvent in each tank and total it. Yes, there is solvent in other places in the machine. But if the machine is not running, those place all have the same amount of solvent every week. We are not concerned so much with the exact total of solvent in the machine as we are with the change in the amount.

The quantity of solvent used can be compared to the poundage records for the same period. It shouldn’t take any more than five minutes a week to track this important piece of information.

Why track solvent consumption? You can compare costs from one year to the next. You can also compare the machine’s efficiency from now to when it was new.

If there is a change in solvent consumption there may be something wrong with your machine or your maintenance procedures. Poundage charts allow you to detect the problem before it gets costly (either in terms of $$ or lost customers).

Some people also track cycle time. This time should not change a lot from load to load. If it has changed, something is wrong – either the operator is overloading the machine or something mechanically is wrong.

Shirt count

Some plants also record how many shirts are pressed each day. The weekly/monthly totals are recorded and compared from year to year.

This information will help you determine when it is time to change the padding on your shirt press. If you are recording the numbers, your pressers will probably work a little faster too.

Virus adjustments

Of course the elephant in the room right now is called Covid. Will you be shut down again? Will your customers ever come back? How will you ever get your plans back on-track?

Even though the virus may have changed your plans, at least you have a map of the direction you are headed. Hopefully you know exactly how far off-track you are. At least with a map you know where to go. You don’t want to be one of those guys walking through the forest in the dark and bumping into trees. Just make some adjustments and keep to the plan.

There is a plus side to this virus. Equipment that is not being used as much should last longer. It may require less maintenance and you shouldn’t have to change the padding as often.

The other thing you should think about is changing your equipment. No, I’m not crazy.

There are a lot of plants closing and used equipment prices have dropped. There may be some newer equipment available. Another thing to consider is that the manufacturers are hungry. They are almost desperate for sales. Distributors are looking for equipment sales and they need to keep their techs busy.

This might be the time to advance your replacement schedule. You might get a much better price. This is all based on the assumption that you have been planning ahead, you know what you need and have put some money aside. If you have access to cash, you may be able to find some good deals.

The bottom line is that, without a plan, no direction you turn is truly informed. Covid or not, there’s always some kind of crisis coming (digging up your street for the next nine months, new zoning regulations, a weather catastrophe, etc.). If you’re aware of where you are and where you want to be, it’s a lot easier to head off in the right direction.