New Equipment Showcase

Installment 1 in the Series

It’s still a long time until the 2025 Clean Show in Orlando (Aug. 23-25, 2025) but we all want to know what’s new and exciting in the industry. We invited dozens of manufacturers and distributors to share the latest and greatest with us. Each week this month we will show more items that have been submitted.

Editor’s Note: Normally, we would edit the descriptive statements about equipment to align with our editorial standards. However, we gave these manufacturers free rein to tell us what is great about their latest offerings. We give them to you here uncensored.

Jensen

Express Pro

This groundbreaking product is the first cornerless feeder that offers true leading edge quality on all linen categories of large-piece linen – even table linen. Similar to the other feeders in Jensen’s Express range, cornerless feeding doubles the capacity per operator hour, and it comes with either two or three feeding stations. Now, thanks to the integration of a mechanical transfer beam, it is possible to achieve this elevated production capacity on heavier and larger linen. An optional quality unit includes a stretch conveyor and spreading brushes for optimum finishing quality without sacrificing efficiency or quality.

Learn more: Express Pro (jensen-group.com)

Kalor

The Kalor is the latest innovation in Jensen ironing technology, combining the best of fixed and flexible chests – incorporating what is referred to as a semi-flexible chest design. As the design is very similar to a standard flexible chest, in offers the same excellent evaporation performance; however, the Kalor utilizes a thicker inner chest plate which makes it more optimal for processing linen with EKG buttons. Furthermore, the addition of a large diameter heated gap piece further improves on the evaporation capacity, effectively adding additional ironing capacity with minimal additional floorspace.

Learn more: Kalor G 1200 (jensen-group.com)

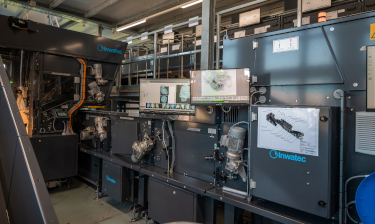

Inwatec Soiled Sort

Inwatec’s soiled sort solution utilizes robotics and Ai to fully automate the separation, identification, removal of foreign objects, and sorting of soiled linen. Far from a conceptual idea for the future, the system is installed in several dozen laundries around the world today, the largest of which processes over 4400 pieces linen per hour through their automated sorting system. The system no longer requires all items to be chipped, and sorting is possible using camera recognition technology. In addition to garments, the system can now process towels, flatwork linen and table linen – with sorting accuracies higher than an operator. By employing robots in one of the least desirable laundry tasks, Inwatec’s Automated soiled sort solution is helping laundries around the world solve their manpower challenges.

Learn more: Automatic Soiled Side Sorting System (jensen-group.com)

See it in action: All eyes on Basel: Explore the new Bardusch laundry ! (youtube.com)

Manufacturers and Distributors — it’s not too late to have your latest equipment featured in this series of articles.

Send the following to becca@fabricarecanada.com: Company name, name of person submitting the information, why you think the equipment is fantastic, and a link for readers to get more information.