Let’s Talk Hydrocarbon Vacuum Stills

By Kevin Marois

Several months back I did an article about perc stills. Now I would like to talk about alternative solvent stills. Because these solvents are combustible, the still has to operate under vacuum. Whether it is Hydrocarbon, Intense, SolvonK4 or any of the other alternative solvents, the distillation process is the same.

The results with a vacuum still are the same as a perc still, but the process is slightly more complicated. By creating a vacuum we are able to reduce the boiling temperature of the solvent. The vacuum also removes the oxygen to help prevent a fire or explosion.

Operation

Solvent is pumped into the still. The vacuum pump turns on, removes the oxygen and creates a vacuum. Once the vacuum is strong enough, the steam will turn on and begin heating the solvent. Solvent vapours are condensed back to liquid in the still condenser and drain down to the pre-separator. The pre-separator is connected to the still and is under vacuum.

Once the pre-separator is filled with clean solvent, a series of valves open and close to maintain the vacuum in the still, but also allow the pre-separator to drain into the water separator. From there the solvent drains by gravity back into the clean solvent tank.

In spite of all the operating parts in one of these stills, it should still be able to cook the solvent from that load by the time the cycle is done.

Safeties

You are boiling a combustible liquid in that still, so there are a number of safety systems to protect you. When you have a problem, do not try to bypass any of these devices. Fix it properly and maintain the manufacturer’s safety systems.

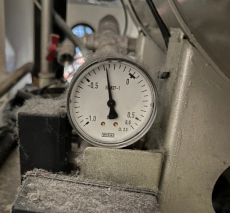

The first device to protect you is the vacuum switch. It has to read the correct amount of vacuum before it will allow the steam valve to turn on to heat the solvent. The gauge on a Union machine reads 0 for atmospheric pressure. As the vacuum gets stronger, the needle rotates counter-clockwise. When it reaches –0.8 it will turn the steam valve on to begin the heating process (–0.8 for SolvonK4 – other solvents may use different readings). Other manufacturers use other styles of gauges, so check in your manual to see what the reading should be.

A vacuum still has several temperature sensors. You should be able to confirm the still bottom temperature on the computer. There will also be a backup temperature sensor to overrule if the primary sensor fails.

Most vacuum stills have a foam sensor to detect if the still begins to boil over. If that sensor is tripped, a valve will open to allow a small amount of air into the still. That reduces the vacuum slightly and slows down the boil. The system works well as long as the foam sensor is kept clean. The system works so well that we have customers who don’t even know what a still boiler over is.

These stills also have a float switch to prevent overfilling. You need to keep it clean so it can move freely.

Maintenance

There are three questions we ask when looking at a problem still.

- 1. When was it last cleaned? (Door opened, not just pumped out)

- 2. What is the vacuum gauge reading?

- 3. What is the still bottom temperature?

Vacuum stills should be cleaned weekly. The sludge can be thicker, so it is best to just open the door and scrape it out. The colour of the bubbles in the still is one way to tell how clean the still is. If the bubbles are white or clear, the still is clean. If the bubbles are brown, the still should have been cleaned sooner. These stills boil more vigorously than a perc still.

Vacuum is critical to proper still operation. If you don’t have enough vacuum, the still will cook slowly – or not at all. There is a switch that senses vacuum and turns the steam on. That switch sometimes fails. If the vacuum is not strong enough, you need to look for a leak. Check that the valves are all closed tight. Is the door gasket clean and in good shape? Sometimes a pin or button gets stuck under the seat of a valve and allows air into the still. No vacuum means no cooking.

(NOTE: If you don’t see the videos below, click on the explanatory text and they should appear.)

Video 1 shows clean solvent cooking in a still. Video 2 shows air bubbling into a cold still. There was a vacuum leak from a fitting for the sludge pump.

The last piece of information is the still bottom temperature. Confirm what temperature is appropriate for your solvent. If the temperature is too low, look at the steam valve, steam trap or steam regulator. If the temperature is too high, the steam pressure regulator may be set too high or it may be failing.

If the still is too slow cooking, don’t turn up the steam pressure. That may actually be counterproductive. The computer reads the still bottom temperature. That temperature will stay at a certain point until the solvent is done cooking. Once that happens the temperature begins to increase. That is how the computer knows the still is finished cooking and turns the still off.

The principle is the same as a boiling pot of water. If you turn the heat up, the pot will boil faster but the temperature does not go up. The boiling water carries away the heat as long as there is water in the pot. Once the pot is empty, the temperature goes up and you have a frying pan instead of a sauce pan. Leave it long enough and the bottom of the pot will start to glow as the temperature increases.

The computer monitors the still bottom temperature. When the temperature starts to increase, it will turn off the still. On a perc still you can increase the steam pressure (temporarily) to offset a problem. If you increase the steam pressure in a hydrocarbon still, the temperature will increase and the computer will turn the still off. The best option is to fix the problem properly.

Conclusion – works well, but different

Vacuum stills have been in use for decades. They work well but they do need to be maintained. Most machines today run a two-bath cycle, with the first bath going to the still. The solvent will stay water-white and the clothes will be clean.