Danger, Danger

This isn’t exactly related to maintenance, but it is a serious concern. My guys are exposed to your poor housekeeping habits and poorly labelled containers. Your staff is at risk, and your customers’ garments are at risk of being damaged. You have chemicals and other controlled substances in your plant. Are you taking proper care with the labelling and storage of those things?

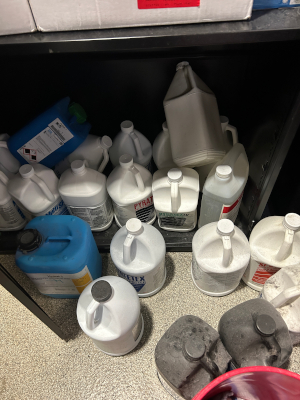

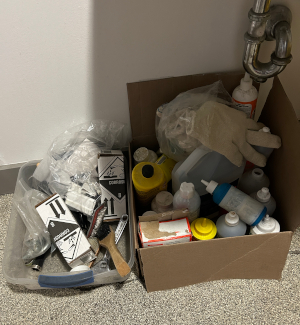

What do we have here?

In your plant you may have solvents and hazardous waste. You definitely have stain removal agents of many kinds – both in use and old products that you have never disposed of. You also have maintenance products: lubricants, glues and building cleaning products. Many of the plants we visit have jugs of product that are 10 and 20 years old. Most products have a definite shelf life. They don’t work anymore; no one knows what they are and now no one knows how to get rid of them.

Compressor oil is not the same as vacuum pump oil. Chlorine bleach and boiler treatment are strong chemicals. I am told that rust remover will go through unbroken skin and dissolve the calcium out of your bones. It is extremely dangerous. Oxygen bleach may be safe for coloured fabric, but it isn’t safe for skin. You need to know what products are in your plant.

Detergent

You also have detergent and other additive products: soap, bleach, starch, fabric softener, booster and texturing agents. Are you using the correct dosages? I watched a lady using a water jug to dump powdered detergent in each washer. It was quicker and easier, but it looked like the 55-lb. washer got almost as much detergent as the 100-lb. washer. That might be good for the soap salesman but it’s not good for you. What about those old pails behind the washer – do you know what they are?

Health and Safety

Most of the things we are talking about fall under a Health and Safety regulation. As an employer, it is your responsibility to keep your people safe.

Do your people remember that your new dry cleaning solvent is combustible? If you put a ‘wet’ load in the dryer, you could cause a fire. When you wipe up some solvent, where do you dispose of the rag?

You and your people may know what is what in your plant, but what happens in an emergency? When firefighters or EMT rush into your plant, are they going to trip over things? Or spill something dangerous or flammable? When things are mislabelled or misused, there is risk of personal injury to your staff. There could be financial repercussions for yourself as well.

Labels

Every controlled substance in your plant needs to be properly labelled. When you put some in a smaller bottle, it needs to be properly labelled too.

See this photo of two spotting bottles. That bottle of POG looks the same as the bottle of chlorine bleach. I hope you remember which one is which.

One time a customer took a bottle off the spotting board and filled the lubricator on his dry cleaning machine with mineral oil. Except the bottle wasn’t labelled and he filled the lubricator with Picrin. All the plastic in the valves melted and glued together. It was an expensive lesson in labelling. Nothing money couldn’t fix…

SDS and Product Sheets

These sheets are provided by your supplier (you may have to ask for them). YOU ARE REQUIRED BY LAW TO HAVE THEM. Your staff need to know where they are and how to find the information they need. They contain information for any kind of emergency: fire, flood, skin exposure, inhalation or even ingestion. Take the SDS to the hospital with the injured person.

Product sheets help you to understand how to use the product properly and in the correct dosage (using the proper amount might save you some money). We visited a plant that was using Hydrocare detergent on their hydrocarbon dry cleaning machine. That sounds great, except that Hydrocare detergent is made for wet cleaning garments in water. It is not for use in a dry cleaning machine.

Training

Now that you have the correct labels and information sheets, you can train your people properly. Use the right product and understand why. So often we hear “Put the red one on first and then add the yellow one.” People try something once and it seemed to work. In fact they may be using chemicals that neutralize each other. It worked once, but don’t understand even what these things are. Know the difference between wet side and dry side; between acids and alkalis.

Get your chemical supplier to do some training for you. They would love to explain which spotting agent to use for a specific stain. The AL Wilson reps are knowledgeable and more than willing to explain what products to use.

Do your people have the correct PPE when they are using that product? Training is a significant investment but it is a legal requirement. Keep your people safe.

Better safe than sorry

You may think that everything is good in your plant, but I bet there are some problems. Ask someone who doesn’t know anything about your operation to look at your storage and labelling. See if it makes sense to them. Be safe and be profitable.

You use many dangerous products, but you use them because they work well. Store and use them correctly and all will be well.