Clean Show 2025 Diary – Day 3

By Becca Anderson

CLICK HERE IF YOU MISSED DIARY DAY 1 or 2

I thought yesterday was busy, but today was even moreso. I attended a seminar, conducted interviews and stopped by an enormous number of booths. Here’s the recap.

CLA does it again

The seminars CLA has put on have been outstanding. A big part of that is due to the fact that they haven’t just taken the mike and told people how to do their business; they’ve had owner/operators on panels who give real-world advice from the trenches. This morning was no exception.

The program was called Spin to Win – Mastering the Laundromat Renovation. Three different owner/operators shared stories and insights of their remodels. First up was Yakov. He bought a much-down-at-the-heels laundromat and stripped it to the walls. Outdated colors, malfunctioning equipment and arcade games that didn’t work (but made odd noises) were first to go. He brightened it up with LED lighting, added upscale vending machines, installed Electrolux equipment (better than his competitors), got rid of the TVs and offered free wi-fi, and put in a new payment system. The result? The location went from 700 customers a month to over 900.

Peter Mayberry has two brands of laundromats – Anytime Laundry for those he buys a building and builds a laundromat in it (like bank buildings), and Washtopia, for when he refurbishes an existing laundromat. One of his former bank locations included the vault, and he turned it into a cool “skill games” room that’s open 24/7. He also kept the bank’s ATM in the parking lot, and gets $1,000 a month from the bank for that. His refurbishments are often of frankly physically unsafe stores, and that’s his top priority to fix first. Then he does all the cosmetic things the others did, and put in new equipment.

Mark Taylor made a mistake when he started collecting old laundromats and refurbishing them: he didn’t rebrand them to one name. He’s going back and doing that now. Mark’s 24/7 Laundromats have the tagline “Laundry NEVER Sleeps”. He’s trademarked both. His vision is “minimum viable product,” meaning putting in the simplest version of a product or service so it can be released to customers faster. It’s not about being cheap or cutting corners, but focusing on key features that matter most to customers.

All three showed before and after photos of their remodels, and then the floor was opened for question and answer time.

Back to the Floor

Maytag

Maytag divided its huge booth up into areas, and in each it offered a “complete solution” to someone planning that kind of installation. Areas included multi-family housing, vended, commercial and specialty cleaning. Some of the highlights:

- A new line of multiload vended washers from 25 to 85 pounds (equivalent to 8 loads). They have touch screen controls that are easy to understand.

- Advantage Line dryers up to 80 pounds, and 45 pounds in stacked configuration.

- Trans axial airflow – so hot air is always touching the load, saving gas and time.

- Commercial machines from 25-85 lbs., with 360 g spin.

- ADC machines from 30 to 460 lbs.

- Specialty dryers for firefighter turnout gear and boots with airflow from all directions, including down inside garments and up into boots.

- Dryers with single phase reversing, with basket that goes in both directions.

I asked them what is next for Maytag. They emphasized that customer feedback drives their innovations. The 85-lb machines are the direct result of customer requests.

The folks at Maytag are proud to be involved in laundry, which affects people’s lives. They know the end users depend on them, and it motivates them to do more all the time. Their partnerships and interactions with customers are another point of pride, with many multi-generational customers.

Sankosha

The big buzz at the Sankosha booth is the Tunnel. In fact, to enter the booth from some directions, you pass through a tunnel, just to be sure you get the idea.

Miguel Hernandez-Livera demonstrated the machine for me. The Tunnel is a thin machine with a small opening in each side. Garments come on slow-moving conveyor, pass into the slit on one side and creep through the machine while being bombarded with hot air. They emerge from the other side looking fresh and unwrinkled. Think of it like the old pizza ovens at restaurants with timed pass-through for correct cooking.

I saw blouses, slacks, sweaters, even sport coats go through the machine and come out well. Long-sleeved shirts can go through, but would still need the collars and cuffs pressed. Still, a space-saving machine to do basic finishing. Over 150 units have been sold by the company in 4 years. It is said to work well on items like those with Spandex that don’t press well.

Renegade Brands

For a change of pace, I sat down with Adam Short of Renegade Brands, which produces commercial laundry solutions that are asthma and allergy friendly. Many people have a reaction to various detergents and scents, but these are said to eliminate the problem and be safe for the people using them, as well. Primarily aimed at the healthcare market originally, PurePro is used in 150 Senior Lifestyle living communities because of sensitivity. The company also offers solutions for sports clothing (several Canadian teams use their Sweat X product, which is also free of allergens.) The products carry the Asthma & Allergy Friendly Certification Program logo. All products are 3rd party tested. In Canada, you can source them through Bichin Laundry in Vancouver.

Quick stops

I had a chance to see Frank Ziermann, owner of Bowe in his booth. He said the show has gone well for them, and seemed happy with the contacts he’s made.

At the Firbimatic booth I ran into Vincenzo Minarelli, Export Sales Director, in the Firbimatic booth. He said they are featuring some smaller machines for more compact spaces, multi-solvent machines and a green line. (And then he had to go sell a machine. Good show!)

Passing by the Veit booth I saw Christopher White giving a talk about the value of wet cleaning to a rapt crowd.

Unipress

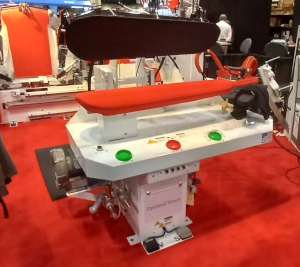

Like many companies on the floor, Unipress was showing a simpler machine. Not everyone needs all the bells and whistles. Robb Johnson showed me how Unipress took one of its popular shirt units and removed the pleaters, took out the rear tensioning plate, and eliminated the arm movement up and down. The result is a machine that weighs 1100 pounds less, has fewer valves and moving parts, and costs less.

I was also shown an integrated vacuum on a dry cleaning press, spotting board and vacuum board. By putting the vacuum on the machine itself, it eliminates the need to pipe the whole plant for vacuum. The vacuum also times out after 5 minutes to save energy, unless the operator taps a floor pedal. Buttons on the unit have also been simplified.

Unipress’s answer to Sankosha’s Tunnel is the Steam Cabinet. Operating like a revolving door, garments are hung on the outside, the door is turned, and immediately hot air is blown at the garments from all directions. Meanwhile, new garments can be hung on the outside, and rotated in when the first load is done. Because of longer dresses that customers wanted to process in it, Unipress has increased the height of the machine by 7 inches. They’ve also moved the controls from above the door (especially now that it’s taller) to the side next to the door for convenience.

Union

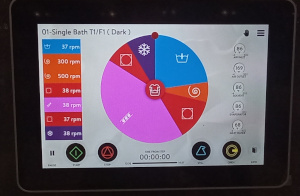

In the Union booth, I met Matt Lipman. We looked at the new touch screen interfaces on the machines, which makes the controls easier to use by having simple icons to tap. Greater information can be carried on a screen than could be on a button.

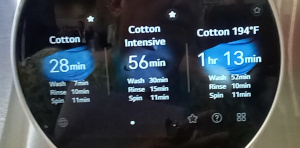

LG

In the LG booth I had the chance to see the latest line of Professional Series machines. These are currently being tested thoroughly in Korea, with US introduction anticipated sometime next year. Again, as with most booths, a highlight was the touch panels of controls, but these were particularly helpful. For instance, instead of just offering three options for cycles, each option had a short list below it explaining the differences in length of time for the wash cycle and rinse cycle, how hot the water would be, etc. It made it easy to see which would be best for a user’s needs. The units come preloaded with 99 different programs, but can be made to display just the ones you want.

“We are careful about testing machines in the real world,” Gustavo Gutierrez said. That’s why such a long time is being given to testing overseas. Lab testing doesn’t cover all the complexities that actual customers would create.

Another area of the booth that they wanted me to see was the new top loader machines. We were joined by David Aycock to get the full story. LG has held off doing a new top loading washer until it could get the agitation right. Their solution is the 4-way TriHelix Agitator. The drum goes one direction, and the agitator goes the other for greater action. The machine fills from both top and bottom for greater speed in a load. A key note is that it uses a direct drive motor without belts – it uses a system of magnets that open and close to make the machine work. From a maintenance standpoint, the machine has just a few screws that need to be removed to get access to areas inside, and the parts of the pump are all interchangeable with any other LG machine’s pumps.

Kannegiesser

Kannegiesser’s booth was perhaps the biggest on the floor. And that can be overwhelming. So they came up with a clever idea to help people learn about everything there. They created a “game” in which participants rotated to different areas of the exhibit and collected a chip each time they listened to one of the experts talk about an aspect of equipment on display. Filling the game board took awhile, but at the end of it I felt I had a good grasp of just about every station in the booth.

Gianlucas Winters explained the robotic feeding machine (RTF) that separates the linens so they are easier for the equipment to separate and send down a speed line. It took engineers quite a while to train the robots to recognized the corners of individual pieces so they could hand them off to each other in the process. Now they do it at a speed of 650-800 pieces an hour.

Henri Peterson took me through the finishing and folding machines. Two were on display—one a quality solution, the other more for speed (used in healthcare settings where the quality of the fold is not of as high a value as the speed with which it’s done.) The quality machine also had features like a lift-up area to move the feeders out of the way so small items could be directly fed to the machine, making it dual purpose. The faster machine had feeders that operators could almost toss the sheets at and have them pulled through the machine, which had brushes to spread them and belts to straighten them as they went to the folder. The Quantex Scanning System above the equipment was lighting up, looking for items that had holes or stains.

Larry Erickson (who has a great podcast on the TRSA channel on this subject) took me through the Smart Laundry eVue plant control system. It features a diagram of the entire plant, and every bag is noted on it. Many users come at the system for different purposes—operators, maintenance people, production teams, leadership. They all have their own need for information, and can log in and track whatever they need, from the placement of a single bag to a whole category of bags, to operator efficiency, to maintenance requests. The app can be downloaded to a tablet, and even viewed remotely from off-premises, since it is cloud-based.

In the realm of Service & Parts, I learned about the Minneapolis training facility. It’s massive, and includes a class area and hands-on equipment test labs. In addition, there is a Pro Support Membership program, which gives 24/7/365 emergency support, access to the KE Academy (training videos), live training seminars and service reviews, for an annual fee. Users can also buy hours of support that they use as needed. In the parts area, the interactive system is almost like Amazon for Kannegiesser parts. Users log in and their equipment is listed. A click on a piece of equipment brings up a list of all consumable parts, and the option to put it in a purchase basket or on a “wish list” if the part is not quite ready to replace. The video center gives instructions on how to maintain machines. Manuals and schematics are also included in the package.

Jacob Askam took me through the pieces of equipment involved in the rail system and the dance of moving linen from one place in the plant to another ergonomically and efficiently. Various linen sorting and bagging options were reviewed.

Finally, Newly Caudle showed me the PowerTrans Vario tunnel washer, and the unique way each section of the tunnel maximizes agitation and compression using an active drop motion as the load is being agitated. Quick exchange modules are included in the tunnel that may extract or heat the load as it moves along. He emphasized the Care Wash philosophy, in which machines are polished inside and out to prevent snags or damage to the items in the load.

He ended the tour with a view of the Power Swing 180 washer/extractor.

The unique feature of the machine is that it rotates the opening upward 90 degrees for loading from above. As the linens are being added, it is already rotating, to maximize the full use of the machine. Active weighing throughout the cycle helps operators know when all the water is extracted. When the load is ready to be emptied, the machine rotates another 90 degrees, this time downward, so the load comes out the bottom.

Of course, I got all my chips, and had the satisfaction of knowing I had a much better idea of how all the various parts of this booth fit together on the floor of a plant.

I’m off for home tomorrow, but feel that this trip to Clean was the best one I’ve ever had. I was able to see many old friends and make new contacts (or make them in person at last) that will make doing business easier in the coming year.

Whether you attended the Show or not, be sure you’ve already marked your calendar for the next one: July 15-18, 2027 in Las Vegas. I’ll see you there!