Maintenance in 12 easy bites

By Kevin Marois

It can be overwhelming to look at the total list of things you need to maintain all year. So I’ve broken it down into 12 easy bites for you – a calendar year of maintenance items you need to take care of.

Most people just ignore maintenance. They fix whatever is forced on them. The press stopped working today so I guess we will have to fix it. I’d suggest you become proactive and fix things before it is an emergency.

Feel free to move these things to whatever month suits you better, and customize it to match your equipment and building. I have also attached some of the check sheets that we use to track our maintenance. They may need some adjustment depending on the brand of equipment that you have.

January – Presses and Planning

Check your dry cleaning presses and form finishers. Check the steam and air timers. Inspect the padding. Make sure the steam and vacuum valves are working properly and not leaking. These things get worse very gradually so it is harder to notice a problem.

This is also a good time to review your procedures. What preventive maintenance are you doing? Review your equipment replacement plan (or make one). Lay out your maintenance budget for the year. Are you tracking maintenance costs?

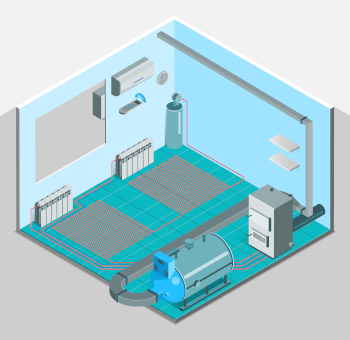

One other thing: check that your boiler room auxiliary heater is working. It is extremely costly if you freeze up. If the temperature is cold enough, it is worth running your boiler a few hours even on a day off.

February – Shirt Press

Shirt presses need lubrication, cleaning, new padding and lots of attention. Take the time to make sure they are working properly. A poorly operating shirt press will seem to keep operating, but the shirts require a lot more touch-up. If you don’t take care of it, you spend more in wages than the repairs would cost.

March – Washers and Dryers

Today’s washers run with very little trouble. There are a few things that you should check, though. Water valves can fail to open or close. You might not get enough water or it might continue filling during the entire cycle. It may also leak down the drain even when the machine is not running. Put your head inside the drum and listen for water running. You can also look at the drain pipe and see if there is water leaking when the machine is not running.

If you see water leaking down the drain while the machine is running, the drain valve may be clogged with some debris, or the seal may be worn. This would also be a good time to check that the detergent pumps are working properly.

Inspect the lint screens on your dryers. You should vacuum out the lint above the lint screen and around the burner area. We inspect the drive belt and check the temperature that the dryer is running at.

April – Building and HVAC

Spring is coming. You need to turn on swamp coolers and inspect exhaust fans. Get your building ready for summer operation.

If you have a chiller or cooling tower, check it now. The summer heat will be coming soon. HVAC systems are usually under a maintenance contract. You don’t do the work, but you do need to confirm that the maintenance has been done on them.

May – Other Equipment

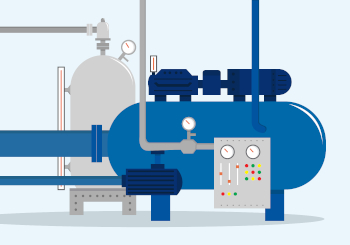

Historically, May was always a good month and hopefully you are busy. Make sure all your ancillary equipment is working. Check that your water is soft. You can buy water hardness test strips. It take two minutes to test.

Service the air compressor and air dryer. Clean up all that lint so things cool properly in the hotter weather. Check the vacuum. Lubricate it and make sure the drain valve is working.

June – Dry Cleaning Machine

The dry cleaning machine is one of the most critical parts in your operation. Each machine manufacturer has maintenance recommendations that need to be followed. Our check sheet, which you can download, is based on the maintenance for a Union Dry cleaning machine. It is a lot of work, but following it will save you solvent, time, and help you produce a better product.

July – Cooling System

Service your swamp coolers and HVAC systems.

Inspect the presses and form finishers.

August – Training

August may be a slower month, so it might be a good time to do some training with your people. There are maintenance procedures that they should be doing themselves. Make sure they are following proper procedures – they sometimes slip and bad habits creep in. Take the time to make sure things are being done properly.

September – Building

Shut down the swamp coolers. Clean the exhaust fans. Check that your furnaces are all working properly. I would also suggest that you have a small electric heater in your boiler room. Buy the one with the thermostat. You can leave it plugged in and it will turn on whenever it is needed.

It is time to do the maintenance on your shirt unit again. Check the padding and inspect the finished shirts. You should not be doing more than 10% touch-up.

October – Washers and Dryers

See the list from March and the check sheet that you can download. Winter is coming so you should confirm that your make-up air ducts are not blocked. Check that the water heater is working properly and the temperature of the water at the washer is what you need.

November – Delivery Trucks

Most people are now doing pickup and delivery. Are your delivery trucks ready for winter? Spend a little money now so you are not stuck later.

You could also do the semi-annual maintenance on your dry cleaning machine. It is not as extensive but it is good to confirm that everything is working properly. (See June list.)

December

Who is coming down your boiler room chimney? Jack Frost. I have seen some of his work. It is amazing what ice can do. And like most amazing things, it comes with a hefty price tag. Don’t let him in!

At the end of the year, you can pat yourself on the back for accomplishing everything on your maintenance plan. You saved some money on repairs and you reduced your downtime. Repairs are expensive enough. When you do them on an emergency basis and you have people standing around, it gets expensive.

Even if you don’t get everything done, you will have done more than you did last year. You will at least know what you have missed. And if you do some of it, that is probably better than you did last year. Pat yourself on the back!

Kevin and Paula Marois founded Calgary-based Integrity Mechanical in 2003 to service plants in western Canada. He writes on issues related to equipment, its purchase, maintenance and use. You can reach Kevin at office@imicanada.ca or via his website www.imicanada.ca