Laundry Design Group

SERIES: Consultants in the Spotlight

Bob Corfield was looking to leverage his years of experience building and equipping laundry plants with Jensen, Washex, GA Braun, Voss Passat, and Kannegiesser equipment and to assist companies with independent consulting services for advanced automated textile processing. The result was the formation of Laundry Design Group LLC (LDG) in 2011.

Laundry Design Group Canada was formed in 2017 to support growth of LDG’s Canadian customers. LDG Canada has supported all sizes of laundry facilities from small on-premise laundries to larger highly automated facilities. LDG Canada’s clientele has continued to expand with hospitals or health regions, Long Term Care facilities and hotels.

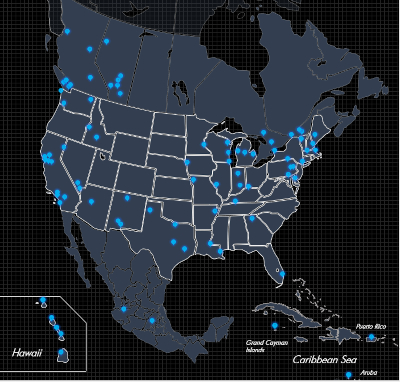

LDG (US and Canada) supports healthcare, hospitality, resort and casino and Food and Beverage laundry operations from its offices in Las Vegas, NV and Calgary, AB.

Areas of Expertise

LDG provides consulting and project support services specializing in the assessment, design and development of commercial laundry facilities. LDG focuses on strategic planning and business plan development, facility assessments, plant design/layout, equipment sizing, managing the RFP process for equipment selection and procurement, and project management of new builds and retrofits for all sizes and types of laundry operations.

In addition to the plant design and construction process, LDG integrates a strategic planning and financial modeling aspect. Tanis Conron, CPA and Managing Director of Laundry Design Group Canada, utilizes her extensive accounting expertise to simulate the financial impact of potential strategies which is required for clients to decide on the best and optimal solution. The assessment and strategic planning area of the company has greatly expanded as health regions look to expand or create more efficient operations. Laundry Design Group Canada has supported provincial health services in Alberta, British Columbia, Ontario and Quebec.

“The complex nature of undergoing a commercial laundry plant design and construction continues to be a growing need,” Corfield said.

Getting Started

We always start with what our clients are looking to solve,” Corfield said. “Whether it’s a new build or a client with an existing facility looking for growth, risk management, emergency planning, consolidation, or market expansion, we seek to understand all aspects of our client’s current state so we can make recommendations tailored to their goals – volumes, types of linens, comfort with various levels of automation, etc.

“Then, along with developing conceptual plant designs, we use extensive financial modeling to explore the cost/benefit of multiple approaches to help clients make solid informed decisions aligned with long-term goals.”

Proof is in the Pudding

We asked if LDG could share the stories of some of its successful projects. They were not hesitant to do so.

“No project is too small,” said Corfield. “Laundry Design Group has assisted with over 200 projects from smaller on-premise laundry operations to large-scale 60m pound processing facilities. In Canada, LDG is involved with a number of healthcare projects that require expansion and retrofit of the supporting laundry facilities, as well as the design and equipment selection for new long term care facilities being built.

“Within Canada, while Bob was with Kannegiesser, he was the project design lead for the HLS Linen Services plant in Ottawa.

In the USA, LDG recently (Spring 2024) assisted with the replacement of 3 tunnel washers/presses and complete dryer shuttle system for a plant supporting the Mayo Clinic in Minnesota. LDG provided design, budgeting, finance support, procurement and overall project management. This $10m plant retrofit was accomplished with no service interruption to the Mayo Clinic or other customers.”

The Mayo Clinic project involved a great deal of planning and logistical forethought. It involved the changing out of one tunnel/press in four days, then two tunnel/press systems in three days. Finally, they changed out 14 dryers and replaced them with a 16-dryer system shuttle automation in just six days.

“The laundry never missed a delivery! Planning for any retrofit is key,” said Corfield.

So why don’t companies call in consultants?

There is a decided reluctance to tap into consultants, even when a project is large and complex. We asked LDG why that might be.

“Depending on the complexity of a project, most operators feel they can run a project themselves or with a trusted vendor,” Corfield said. “We usually get the call when they realize they still have to run their business while running a complex project, and they run out of time. Usually, we are brought in when the client simply cannot decide the best option for their project.

“Often a plant owner feels that they can get ‘free’ consulting from a vendor who provides drawings with solutions they [the vendor] offer. The miss here is the narrow limits of single-vendor solutions. A true consultant is not bound by vendors’ solutions and can provide unbiased financial models to support any decision related to budgets and expected outcomes,” Corfield said.

What’s a consultant cost?

One of the main things that stops a business owner from picking up the phone and contacting a consultant is fear of what that call will cost. A clear understanding of the value of hiring someone who already knows the lay of the land is critical in making that decision.

“We always start with the initial needs assessment,” said Corfield. “Can the goals be met? Is the expected budget reasonable? If we are comfortable with our ability to assist, we move forward with a tiered fixed-fee schedule with defined outcomes for each tier. To use a football analogy, we can be in booth, on the sideline or on the field – each role has a value and a defined responsibility.”

What do you REALLY know?

You’re great at what you do all day long. You have a strong team and have developed a loyal customer base. But what do you know about construction?

“Designing and building efficient laundry operations is more complex than most people think,” Corfield cautioned. “If you have NOT been in a major construction cycle or plant retrofit within the last 5 years, there is a substantial risk to making costly mistakes, as the market has changed considerably. If we do our job right, we (LDG) will not cost you anything — as we can save you time, money and, most importantly, meet your goals faster. That helps you preserve your financial performance.

“Because LDG is not connected to any one equipment or systems vendor or contractor, we provide recommendations that meet the unique needs of the client. We are helping our clients procure over $20m USD per year, which means we know what is a fair price for equipment and services, and how to budget effectively.”

More information

To contact Laundry Design Group, use the information below.

www.LaundryDesignGroup.com

Office locations: Las Vegas NV and Calgary AB

Ph: 855-226-3500

Email: admin@laundry-design.com