Clean Show 2025 Diary — Day 1

By Becca Anderson

It’s wonderful to sit down and type this first installment in my Clean Show diary — actually, it’s great to just SIT DOWN. There is a lot of walking involved in a Show, and I’ve done more than my share today.

Let me give you a sampling of what I saw on the first day of the Show.

Education first

The day began at 8 a.m. with the education sessions. I attended the CLA’s Top Trends in the Laundry Industry. This involved president Brian Wallace interviewing five people who have very different approaches to the laundry industry:

- Bhavin Patel of SpinXpress Laundry, entered the industry with the intention of changing it. His company is 8 years old, he has 30 locations and 6 more underway, with 12-15 opening next year. His locations are tech-heavy, bright and inviting. His company appeals to the new laundromat customer, and he’s raising expectations of customers as to what a laundromat should be like.

- Sara Wendt of Linen Fresh Laundry is in the business of acquiring and upgrading laundromat locations across the country. Her company is funded by growth equity investments. Her company gives investors a platform to get into the laundromat space, without having to evaluate locations for themselves.

- Saichell MacNeille, of The Washroom Laundry Service, offers full service pickup, laundry and delivery services. She partners with local laundromats and gives them the ability to do pickup and delivery through her company, while they process the laundry she picks up.

- Nick Raehsler is from The Laundro Company, Wow Wash Coin Laundry. He started in the industry with no experience and has learned a lot on the way to opening 4 stores — so far. One is in an old bank building. He told a touching story about how he got one of his most valuable employees. He said, “Master delegation, and you will have 30 stores some day.”

- Mark Vlaskamp of LaundroLab/2ULaundry had a delivery service but no laundromat. He needed one to control the quality of the cleaning that was being done. He fell in love with laundromats and acquired laundromats as production facilities to run alongside his delivery service.

Each speaker came at the industry from an interesting viewpoint, and had lots of good tips for attendees. And there were a lot of attendees. More chairs had to be rounded up to handle the crowd.

A second CLA panel followed the first session, entitled Five Ways to Grow Residential Delivery & Commercial Accounts. It included a moderator and four panelists, plus question/answer time at the end.

Hit the floor!

I was eager to get to the Show floor itself, and followed the crowd down to the hall. The explosion of sights, sounds and experiences was overwhelming. I saw a few first-timers stop dead in their tracks with their mouths open. It’s that kind of Show.

I visited Braun’s booth, where they showed me around. They are emphasizing their Streamline Ironer, which takes up less space and is more versatile than previous ironers. Braun is also one of the leaders in making the equipment more user-friendly through on-machine screens that give more than just error codes — they display a drawing of the actual machine and highlight the exact area that needs attention, then spell out what must be done. No more scrambling for manuals!

It seemed natural to wander a few booths over and visit Jensen. They, too are all about efficiency and the ability of the operator to get exactly the information needed right from the machine. Using QR codes (which can be retro-added to existing equipment) all the information is at one’s fingertips.

In addition, any load at any stage in the plant is trackable through the system. The time a load enters the system is noted, and the operator can see where it should be at any moment. If it is not where it should be, it can be tracked back to where it had an issue. The use of cameras throughout the plant helps with tracking, as well.

The Inwatec robotic sorting system is set up in the booth with other pieces of equipment to show a whole system utilizing this innovation. First introduced in 2018, the robotic sorter is now incorporated in laundry facilities all over the world.

Jensen also held an over-lunch press conference in which both technical people and marketing folks explained all the new innovations in its equipment, and fielded questions about specifics.

I also visited with Lavatec, where I learned about their AI assistant, Tumble. Again, the purpose is to help the operator have immediate access to any information needed to keep the machine running. Tumble may look like a cartoon, but it is designed to field questions and alert operators to problems.

Just like an online AI, you can ask Tumble a question in plain English. No need to input technical stuff or fumble for a manual. Want to know how the machine is doing? What is happening in the spin cycle? Just ask it. Need to know how the overall load is doing? Tumble knows.

In addition, the both is displaying the Vega line of feeders. The partnership of Lavatec and Vega seems to work well. Lavatec equipment cleans the laundry, Vega does the finishing. One innovation on the Vega system is the ability to fold different sizes of items, and have them come out on different stackers, making packaging much easier. They are also featuring two towel folders — one that uses air blasts to fold; the other uses arms. Each has its purposes.

Across the floor, PayRange had set up a mini laundromat in which to demonstrate its on-the-wall kiosks in three sizes. The company offers cashless payment systems in just about any currency vehicle you can name, including Venmo. This sets it apart from others.

They are now offering a subscription-based service model, in which the customer selects whether they want just cashless payment on machines, or also a kiosk, or also a POS system (for Wash/Dry/Fold operations). Subscriptions start at $199 a month for 50 machines. They’d already had some buyers by the time I visited the booth.

More education

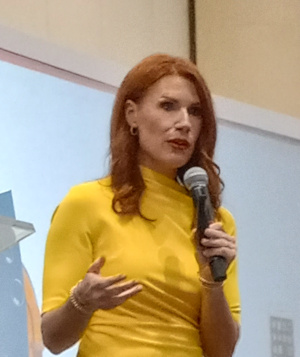

I then attended a fascinating presentation in the education area on the floor called Generational Fluency. Presented by Jessica Stollings-Holder, co-founder of Regenerate, the talk helped everyone in the audience, no matter what “generation” they are from, to better understand the other generations and how we can all work together by adjusting to each other. Some key points:

- Generational tags shouldn’t be used to stereotype people, but as a lens through which to see each other more clearly.

- Generations run in cycles. The optimist generation is followed by the more conservative people, followed by the peacemakers, followed by the builders/makers. We are at the end of a full cycle, and so it feels very chaotic.

In describing the various generations (Baby Boomers, Gen X, Millennials, Gen Z), the speaker gave clear areas in which they are different, and what it will take to work together productively.

Enough sitting!

After that nice rest, it was back to the floor for a few more minutes before the end of the day. I caught sight of a robot loading a conveyor system, and another picking up individual pieces of cloth. I stopped in — this was the Spindle booth. I learned about this interesting technology (works with any conveyor system) that has the robot arm reading the RFID chip on a uniform shirt and then slotting it into a precise spot on the conveyor so it can be offloaded down the line into the right order.

A group of people wearing headphones were enjoying a talk in the booth about how the arms work and what they can be used for, what obstacles had to be overcome for them to operate, and more.

Time to relax

After a full day of education sessions, interviews, and floor visits, I was ready to knock off for the day. I, along with a lot of other people, headed over to the TCATA/DLI reception. I ran into Darcy Moen there, as well as lots of other people I hadn’t seen in a few years. It was the perfect way to end the first day, and the variety of nibbles plus roast beef sandwiches with horseradish sauce were much appreciated!

Of course, in a show like this, it’s never really over until you are back in your room and can put your feet up. For me, that meant a 2,281-step walk back across the whole convention center to my hotel. But my, it’s good to sit down!

Tune in tomorrow for more of my Clean Show Diary!