Page the Cleaners: 90 Years Strong

Page the Cleaner of Edmonton, AB was founded in 1935. They are justifiably proud that they are celebrating 90 years in the business this year. General Manager Rupinder Rudolph was delighted to hear her plant had been nominated to take part in this competition by Chris White of Kreussler. Chris travels extensively to plants, and knows when he sees something he likes.

White said, “They built a new plant several years ago and have even updated it recently. Rupinder has built an amazing management system and team to make that place really hum.”

The Basics

Page the Cleaner has 2 locations and 4 routes around central Alberta. The company has 25 employees, and they use both K4 solvent (for personal dry cleaning) and perc (for industrial cleaning of coveralls.

What makes your plant special?

“First and foremost, our people,” Rupinder said. “This might sound cliche, but the most important factor in making our plant incredible is our awesome staff.

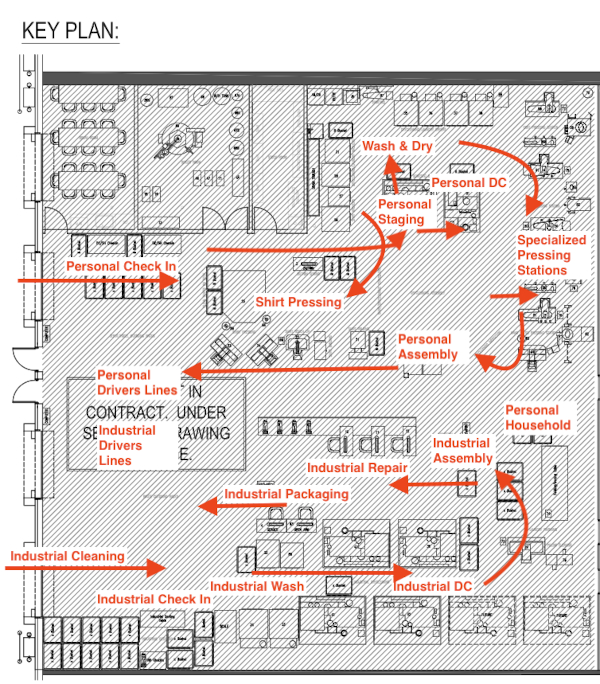

“We also have two separate sides to our plant: industrial and personal. Both have been deliberately designed to flow in a loop from the doors where our delivery drivers bring things in and back,” she said.

“We have also incorporated repair into our industrial line. The items loop through check in, cleaning, assembly and then to repair. Finally they are packed and returned to the drivers’ lines for easy loading.”

There is a conscious effort to make the plant better. “We are always looking for ways to improve flow and efficiency,: she said. “We have clear signage, a simple re-stocking system, a custom-built maintenance program, and a lot of documented standard operating procedures to ensure consistent training and results.

Separate, but Together

“We do a lot of coverall cleaning for heavy industries such as construction and oil & gas. This cleaning requires a dedicated area and equipment, due to the heavy soiling.

“Our ‘personal’ plant side handles all laundry and cleaning for retail customers, and restoration cleaning,” Rupinda described.

”The goal is to have each item travel smoothly through its respective side and arrive back at the driver lines. Some routes have only industrial or personal, and others have a mix of customers.

The advantages to the two sides model:

- There is a simpler process for coverall cleaning (no spotting, no pressing). Having it separate allows smooth flow and high utilization of dedicated machines.

- Coveralls can be really dirty/greasy. It’s good to have them away from “personal” cleaning areas.

- We can utilize a different solvent for different cleaning types (perc is most effective and safe when it comes to removing oil and grease and maintaining the FR [Fire Retardant] rating on coveralls, but K4 is more versatile and environmentally friendly, making it more suitable for personal items use).

- Having both sides connected allows for cross training and moving team members between the two sides when needed.

- The steps are laid out in order so that the garments travel smoothly through the plant.

SEE DIAGRAM AT THE END OF THE ARTICLE FOR THE

FLOW OF WORK THROUGH THE PLANT.

How do you market Page the Cleaner?

- Social media — LinkedIn, Instagram, Facebook

- Google Ads

- Website & SEO

- Trade shows & golf tournaments

- On-site retail counter marketing, signage, branding, etc.

“We get a lot of great comments from customers,” Rupinder said. “We just passed 300 comments for one location, and are almost at 200 for our other location!” Some examples:

- Always friendly and my items are always ready on time. This location is close to my house too so I like coming here best! They offer other services such as tailoring and even have donation bins for the homeless. Great place all in all! — Brianna

- I must say, Page the cleaners is by far the best when it comes to dry cleaning Bespoke suits.. I literally drop off 3 to 4 full suits and not only do they do the best job but it’s very affordable. I always end up paying less than $100.!! Staff is very friendly and I will definitely continue to be coming here!! – Omar

- I had an oversized down comforter that desperately needed cleaning but it was too big for my washing machine. I decided to try Page The Cleaner in west Edmonton, and was quite happy with the results. The price was as expected, and I was able to pick it up after two days. — MSY

- Started using Page for cleaning my work coveralls. They do a good job, the prices are reasonable, and the staff are friendly. I’ve started recommending my coworkers to them as well. — Anthony

What challenges have you come through?

“We have had many challenges as a company,” Rupinder said. “In 1999 our family purchased the company and it was in a very tough spot financially. Page was a franchiser with several corporate locations and many franchisees, and the main plant was very old and decrepit.

“Over the past 15 years we made the tough decision to move away from franchising as we realized that we did not have cultural alignment with our franchisees. This was challenging as it took Page from a brand with over 20 retail locations to just 2 today. But sometimes you have to tear it down to build it back stronger.

“About 10 years ago we had to move our plant, which took several years of planning and was a huge investment.

“This unfortunately was followed by a major oil downturn, which hurt our revenue and resulted in two of the worst years in our company history in 2017 and 2018. We made some good strides towards recovery in 2019 but then 2020 hit. Everyone in the industry knows how tough COVID was on dry cleaners, and it was really tough on us. In mid 2021, about a year into COVID, we decided to make major management changes and really focus on improving our systems and processes, and to clean up our stores and plant.

It has taken many months and a lot of hard work from our team, but the results have been incredible,” she said.

What’s ahead for Page the Cleaner?

“In January 2024, a partnership of family and non-family management purchased Page the Cleaner from our parents, and we have continued to focus on diversifying the business and pursuing operational excellence,” Rupinder said.

It’s clear that, through the ups and downs, the focus at Page has been to do the job as efficiently as possible, with happy employees and a clear vision for who they are and where they are going.

Work flow in the Page the Cleaner plant: