Open Your Eyes

I have been thinking about Health and Safety lately. We have been talking with our guys about things we need to be careful about. We came up with a list of things that customers (YOU) most often ignore. Things that have been bad for so long, no one even recognizes that problem anymore. I’d encourage you to have another look at your plant.

Accidents happen at times when you don’t expect them – or in ways you didn’t anticipate. Someone may walk through your plant to use the bathroom. Or maybe one of your children is running around. What are you doing to avoid having someone get hurt? You need to out-think the unthinkable.

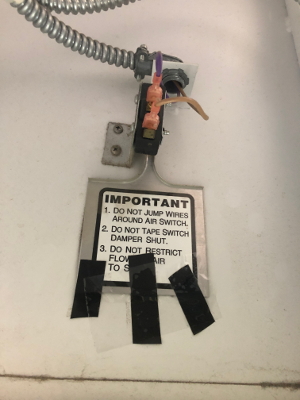

Dryer Sail Switch

This is the one that really got me started on this article. We went to a plant that was having trouble with a dryer. See the wording in the photo? The dry cleaner questioned the tape but a ‘professional’ told him it would be OK until he got it fixed properly.

The sail switch on a dryer is a safety device to ensure that the fire is turned off if there isn’t sufficient airflow. If you have the fire on without enough airflow, the temperature gets much hotter and you may cause a fire.

You need to fix the problem with airflow, rather than bypass the safety system. The reason the sail switch on this particular dryer wouldn’t close was because the 8″ vent had been reduced to 6″. That limited the airflow and caused the fire to not turn on all the time. Don’t jury-rig it, fix it. You work with equipment that can cause harm, injury or even death.

Unlabelled Containers

Do you have unlabelled containers? What about the bottles on your spotting board? Bleach instead of Tannin. Oops, you just bought that jacket. What about your maintenance supplies? Oils, cleaners, etc. I know of a plant that had Picrin in a spotting bottle that was labelled Air Oil. They filled the lubricator on the dry cleaning machine with Picrin and melted all the plastic in the solenoid valves. That was an expensive mistake. How much does a Sharpie marker cost?

Missing Button Guard

Some presses use a single button to close the press. That button normally has a guard over it. Sometimes when the switch is replaced the button guard is not reinstalled. I have seen a few times where someone drops a lint roller, it hits the button and the head jumps about halfway down. Just enough to smack someone on the head or the arm. Safety guards are engineered for a reason, and the reason is the operator’s safety. If the guard is not reinstalled, insist that it be done.

Switched Foot Pedals

Some pressers are short and cannot reach the vacuum pedal when working on the nose of the press. The easiest solution is to switch the wires for the vacuum and steam pedals. Now you can reach the pedal. If you are the only one in the plant that might seem to work. But what happens when you hire a new person? They put their hand on the buck to smooth out the garment and turn on the steam instead of the vacuum. You caused that injury. Why not put an additional pedal on a cord so that the presser can reach it easily? All equipment should be safely usable by anybody working it, whether it’s you, your lifelong presser, or a substitute while someone’s on vacation. Surprises mean injuries.

Junk on top of the Dryer

Your dryer has a nice flat shelf on the top. And when we look up there we see melted plastic bags, wedding boxes charred brown and piles of black lint. I know it’s just a little too tall for most people to be able to see up there without getting out a step stool. Out-of-sight may mean out-of-mind, but it doesn’t mean safe. Anything on the top of a dryer is a fire hazard.

One time when were we were installing a gas dryer, the Gas Inspector made us install a cage around the top of the dryer so nobody could put anything on top of it. It’s that important.

Missing Belt Guards

Why is it that people do not reinstall covers on machines? Many plants have exposed belts and pulleys, just waiting to grab an inattentive finger or hand. Even worse than the missing belt guards are the missing chain guards. Chains and sprockets could cause some very serious injuries. Every one of those machines came from the factory with a guard. If it isn’t there it’s because you took it off and lost it. If someone else lost it, then have one made. It’s not that difficult.

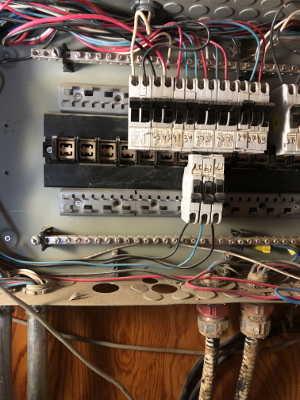

Unlabelled Valves or Breakers

You have no idea how often we try to turn off a machine and the breakers are not labelled. Sure we can keep flipping breakers until something happens – but that something may be that I turned off your POS computer and you just lost your data. If we can’t find the correct breaker, sometimes we have to try to fix something live. All this fooling around costs you more money. When the electrician does some work, make sure he labels everything. It’s easy to do when he is there and working on it.

The same goes for valves. Is that an air valve or a gas valve? That pipe is hot … is it steam or condensate? Pipes need to be labelled – especially when they go through a wall. It will save time on repairs and it may prevent an accident.

Missing Insulation

Many plants do not have adequate insulation on hot pipes and machine parts. Sure, we can work on it hot, but it takes more time. The bigger concern is not the mechanic but the presser who works there every day. Those uninsulated pipes make the building hotter, increase the cost to produce steam and the cost to cool the building, and they are a safety hazard. And don’t tell me ‘everyone knows about that hot pipe’. Accidents happen. Your workers deserve a safe place to work. Burns should not be the norm for anyone who works there.

Leaking Pipes

We have seen some creative ways to stop leaks. A self-tapping screw will plug the hole in the pipe. Cotton string tied tightly around a pipe will shrink and seal the hole when it gets wet.

We all do what we need to in an emergency. But you still need to come back and fix the problem. Leaks cost money and can be a safety hazard. An emergency fix is not a real fix.

Conclusion

Equipment manufacturers build equipment that is safe to use. You need to maintain those safety systems, the electrical interlock switches, the belt guards and anything else that they designed into the machine. The manufacturers are trying to protect you – not make your life more difficult.

Most of these things we have talked about could cause serious injuries, and you’d be responsible. Don’t tell me Workers’ Compensation covers you. It doesn’t protect you if you have been grossly negligent. I could tell you about injuries and fatalities, about lawsuits. But I think you understand. When you go to work tomorrow, think about the fact that your workers lives are in your hands.

Why am I telling you all this? I am trying to take care of my guys – even if you aren’t taking care of yours.

Kevin Marois founded Calgary-based Integrity Mechanical in 2003 to service plants in western Canada. He writes on issues related to equipment, its purchase, maintenance and use. You can reach Kevin at office@imicanada.ca or via his website www.imicanada.ca