Let’s talk detergent pumps

Over the years we have covered maintenance in most areas of a dry cleaning plant, but I don’t think we have ever talked about detergent pumps.

No! They are not soap pumps. Soap is made from natural ingredients like lard and lye. The products you use are synthetic man-made detergents and additives. We are professionals, so I think we need to understand and use the correct terms. (Sorry – I’ll get off my soap box now.)

A detergent pump automatically injects detergent (and other additives) into the washer as the cycle progresses. The pump can inject liquid: detergent, degreaser, bleach, fabric softener, neutralizer (sour) or even water repellent as required.

Advantages of a pump

There are several benefits to using a detergent pump. You gain precise control of the amount of product that you are injecting and when it is injected in the cycle. It is possible to make multiple injections during a cycle without the operator having to attend to it.

You can create multiple cycles for the different kinds of work that you process. You can process your work with the minimal amount of time, water and detergent.

When you use powder detergent it is easy for the operator to put in a little more or a little less. It is difficult to get consistent dosing.

Another advantage you gain is the expertise of the technician who maintains the pumps. He knows laundry and can tailor your wash cycles and detergent injections to match your loads.

The new washers have better control systems and you can leverage that with a detergent pump system. Some of the new washers will weigh the load before starting the cycle. Based on that weight, they will vary the water levels and the detergent amounts going into the wheel.

Does liquid detergent cost more than C***co detergent? Yes – because it is not half filler. Plus, if you consider the cost of your operator’s time and the improvements in quality, it is not a difficult choice to make.

Last benefit of a detergent pump system – you don’t have powder sprinkled all over the floor.

How does it work?

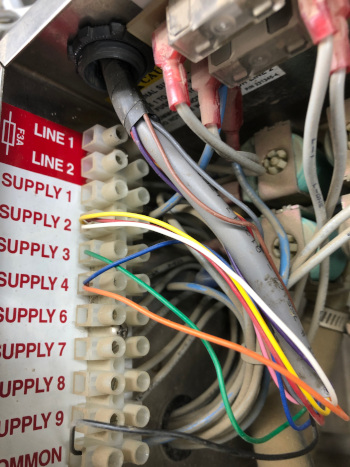

The washer sends signals to the detergent pump indicating which product to pump and the correct amount to put into the load. It might call for detergent two or three times during a cycle. Then it may call for fabric softener. Or if the work is going to an ironer, it may signal for an injection of sour (neutralizer).

If you have a soft-mount washer, it will control the detergent pump directly. Older hard-mount washers may require you to select the appropriate detergent cycle to go with the wash cycle you have chosen.

Another advantage to the detergent pump system is that you may be able to install the pumps and detergent pails in a remote location in the plant and just run a single hose to the washer. The additives are flushed into the washer with a stream of water.

Maintenance

Even though things happen automatically, it doesn’t mean that you can completely ignore your detergent pumps. The biggest problem we see is that the pails do not get replaced when they are empty. A pail may last a month or even two – just long enough for you to completely forget about them.

The pails should be checked weekly. Then when you know a pail is almost empty, it should be checked daily. It sounds simple but they get forgotten all the time.

We mark the levels on our pails every month. Then we can track how fast the product is going down. If there is something wrong with the pump, it becomes obvious when the level doesn’t drop.

On regular laundry, if the pump doesn’t work, you may have a load that has to be rewashed. If the pump fails on a wet cleaning load, you may have damaged garments to deal with. Checking these should be part of your weekly routine.

Changing squeeze tubes is not difficult. I would recommend you learn how to do it and keep a spare tube in case of emergencies.

Expectations

It may sound like detergent pumps are the best choice for everyone. That is not always the case. There are two issues and they both relate to your volume (the number of loads you process).

Detergents or additives need to be used in a reasonable amount of time. Softener can thicken and become unusable. Bleach will lose its strength. If you don’t do a lot of volume, liquid products may not be the best choice for you.

The second issue is the cost of the pumps and installation. It could easily cost $1,500 to install a pump on a single washer. You may not get a bill for the installation, but someone has to pay for it. The assumption is that you will purchase enough product to cover those costs.

Your distributor also has an expectation that you will use their products for a certain amount of time, and that you will not keep swapping brands of detergent every few months.

If you are busy enough, you can get excellent results from a detergent pump system. Just pay attention to the pails and you will do well.

Kevin Marois founded Calgary-based Integrity Mechanical in 2003 to service plants in western Canada. He writes on issues related to equipment, its purchase, maintenance and use. You can reach Kevin at office@imicanada.ca or via his website www.imicanada.ca