Smart Machines

By Kevin Marois

It’s amazing that the latest equipment doesn’t make coffee for you and do your taxes while you’re waiting for a load. What can they do?

The new dry cleaning machines are fantastic. They have much better control over the cleaning process. You can have a cycle for every kind of garment and every type of soil. They save water and steam. They get better solvent mileage.

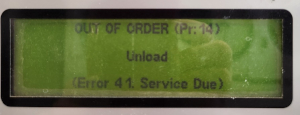

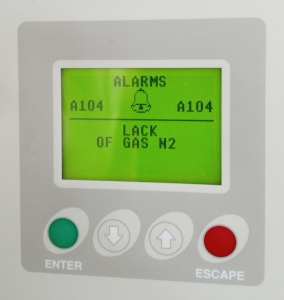

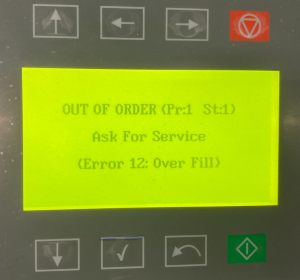

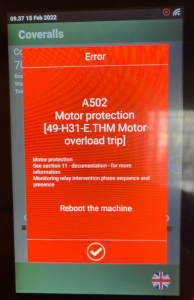

The latest washing machines can diagnose problems, monitor the utilities, track production and adjust detergent usage based on load size. The new machines monitor the supply of utilities and, if there is a lack of steam/water/air, they will shut the machine down before you have a problem. Some machines will even email you when there is a problem. Some machines have training videos and manuals built into their display tablets. Boilers are designed to shut down quickly whenever there is an anomaly. Better to shut things down prematurely than to have a bigger problem.

The new machines remind you to turn on the still, clean the button trap, etc. They also help diagnose things when there is a problem. These machines are easy to operate, efficient and very smart.

Dumb Operators

But as the machines got smarter, the operators got dumber.

It used to be that the operator of a dry cleaning machine was quite capable of running the entire cycle in manual mode. They knew what steps were required and which buttons to press to make each of those steps happen. Today we have operators who can’t even pump solvent from tank 1 into tank 2.

They are operating a $100,000 piece of equipment and they haven’t even spent 10 minutes reading the manual. The value of the garments in the wheel might be $20,000 to $30,000, but the operators can’t accurately describe the difference between the cycles in order to decide which cycle they choose to use. It’s not that these people are unintelligent. They just haven’t been trained or spent the time to learn what they need to know. No one has required them to learn their trade, and they haven’t put in the effort. Either the owner doesn’t care or doesn’t know, so he can’t help. I don’t have a problem with someone not understanding everything about their machine, if they are actively learning. Where I have a problem is when they aren’t interested in learning.

Understand the Process

Some people operate the machine with no awareness of where it is at in the cycle. Whether it sounds/looks/smells like it is running properly. We get phone calls about a problem with a machine, but the person on the phone can’t even tell me if the machine was still washing or if it was drying.

These people are gamblers and I don’t like their odds. Press a button and walk away – the odds are pretty good everything will come out okay. But not 100%. There are garments that should not be dry cleaned and some that should not be washed.

I am all for smart machines, but I also want to see smart operators. Do you know where the dirt goes when you run the dry cleaning machine? What are the different types of soil? They are not all removed in the same way. What difference does a water softener make? Why do you blow a boiler down?

I was doing a repair at a plant one day when the lady asked me how to process a garment. I pulled out the care label to read it. “Professionally dry clean,” I read, and looked up at her. She shook her head as if to say, “No, that isn’t me.” She was probably correct. Even though she owned a dry cleaning store and was the only employee, she wasn’t a trained, competent professional dry cleaner. Want more proof? She called me two weeks later to look at a suit jacket. It had coarse hairs sticking out all over. I looked at the shoulder pads to see if they had come from there. No, they were fine. “What else was in the load?” I asked. “Just this horse blanket” she replied. Well, that explains the hair and the smell. You laugh at her, but she didn’t know any better because she hadn’t been trained. Sorry, I should not say these operators are stupid. They are untrained, inexperienced, unqualified amateurs trying to make a living without knowing what they are doing.

Training

So where do most operators get trained? They don’t. The previous owner will stick around for a few weeks and teach them his bad habits without any understanding of the process. Someone who doesn’t

understand teaches the next person, who teaches the next person. Eventually there isn’t much knowledge, just a lot of myths and ‘try this, it usually works’.

We know of one plant where the new owner received one week’s training. Oh, and that was only mornings. It was stupid of her to agree to that, and ridiculous that the old owner would only offer that – especially considering the hours I had spent trying to help him learn the business.

Ongoing Training

Initial training is one thing, but you also need ongoing training. Talk to the manufacturer’s sales representative. He would love to come to your plant to help you make sure his machine is working properly. You can also take online courses. The Dry Cleaning & Laundry Institute (DLI) offers courses on stain removal, fabrics, and much more. Take them yourself, then you can train your staff. We do a two-hour training session with our technicians every month. It is difficult to do that and there is a cost involved,but we are seeing real benefits.

One last thing while I am up here on my soap box: Learn the correct names of things. We need to be professionals speaking in a professional manner. When you speak to a customer about the placket on his shirt, he recognizes that you probably know what you are doing. If you just say, “This thingy here,” you mark yourself as an amateur.

A lady called a while back and said, “The thing fell off the side of my boiler.” How am I supposed to help her? The problem might be a serious safety concern, or it might just be a piece of trim. Without good info, a mechanic can’t help.

Our customers expect that we are trained, competent professionals. Smart machines are great, but someone must be in control. Hopefully, they are trained craftspersons dedicated to improving their skill and providing quality work.