The Clean Show floor can be overwhelming! Below are some booths we know you are not going to want to miss. (This section will be added to frequently, so check back.)

Fabricare Canada will be EVERYWHERE at the show! We won’t be tied to a booth, so we’ll will be able to attend education sessions, do booth interviews, and spend time with people all over the floor. If you want to meet, just call Becca — 903-215-2313.

BOOTH 2001

The Braun Experience

We’re front and center at Clean Show 2025, and you won’t want to miss it. Stop by Booth #2001 to experience Braun’s most trusted laundry solutions — including high-performance washers, dryers, wash aisle material handling systems, and finishing equipment — all proudly designed and built in the U.S.A.

Here is just a highlight of some of the products we’re showcasing:

- Open Pocket Washer with Water Reclaim – Reclaims up to 225 gallons of water per load, reducing utility costs without compromising wash quality.

- PrimeDry® – A compact, high-throughput dryer (gas or steam) delivering up to three loads per hour with precise heat control and direct drive.

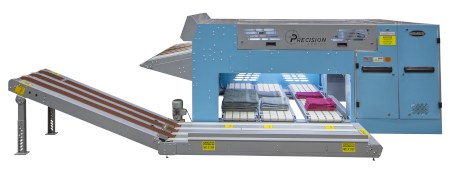

- Precision Series® Topline Air Folder – Auto-sensing folder for towels, scrubs, and gowns. No pre-sorting required — items are folded, sorted, and stacked with precision.

- Manual Ride-On Shuttle – Ergonomic, operator-controlled shuttle for safe, efficient transfer of goods across the wash aisle.

- Braun WashNet® – Powerful laundry management software offering real-time performance tracking, centralized control, and operational insight.

We’re also showcasing what truly sets Braun apart:

- Reliable customer service and parts support

- Expert laundry design, installation, and integration

- End-to-end project management

- In-depth laundry analysis and consultative services

Check out our videos and see for yourself! (Click image to go to videos)

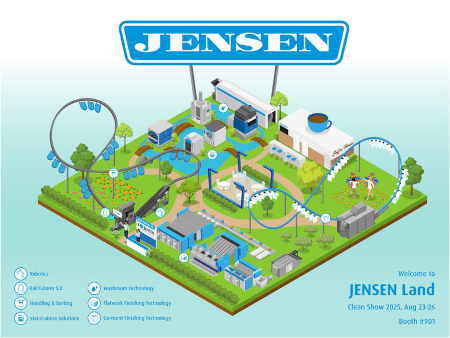

BOOTH 901

Welcome to Jensen Land at Clean Show 2025

This year, Clean Show 2025 lands in Orlando, the theme park capital of the world, and laundry owners are in for a thrill. Right inside the Orange County Convention Center, you will find a one-of-a-kind laundry experience. Welcome to Jensen Land.

At Booth #901, there will be no shortage of excitement, energy, and innovation. From high-speed flatwork solutions to AI-powered robotics, Jensen Land is packed with performance-driven attractions built with laundry managers and operators in mind. You will discover proven automation, product launches that push the industry forward, and solutions that carry the laundry industry further into the digital age.

Whether you are upgrading, expanding, or just exploring what is next, come visit our world of innovation. As your partner, we welcome the opportunity to create the future of laundry together.

A sneak peek at the various attractions of Jensen Land

Express Pro: The feeder speedster

This four-seater ride is the only cornerless feeder designed for hospitality and table linen in two-lane operation. With just four operators, it doubles production capacity while delivering five-star quality finishing, all at record-breaking speeds. The Express Pro feeder with four feeding stations is unique in its category and is shown for the first time in the USA. It has the potential to revolutionize the feeding of table linen. Only at Jensen Land can you experience this kind of innovation in motion.

Inwatec sorting: The sorting summit

At the peak of Jensen Land, you will find a high-tech thrill to automate the soil sort. Inwatec’s solution allows for the complete automation of the soiled side sorting process, powered by robotics, AI classification, and X-ray detection.

With over ten years of continued success and more than 170 installations worldwide, this sorting system is the most advanced system in the world, and it has been rapidly gaining interest thanks to a powerful track record of success.

Rail Explorer 5.0: Lifting the Futurail software to new heights

Step into the control center of Jensen Land with RailExplorer 5.0, our most innovative software yet for Futurail, the automated laundry handling solution for soiled and clean linen. The sorting stations enable laundries to accurately weigh laundry batches into separated categories and/or customers for precise wash codes and routing to the correct finishing equipment. They now come with an upgraded software: RailExplorer 5.0 brings a sleek, intuitive interface and real-time system tracking right to your fingertips. With simplified troubleshooting, improved dashboards, and full production optimization across both the soiled and clean sides of the laundry, RailExplorer 5.0 takes visibility, control, and performance to the next level.

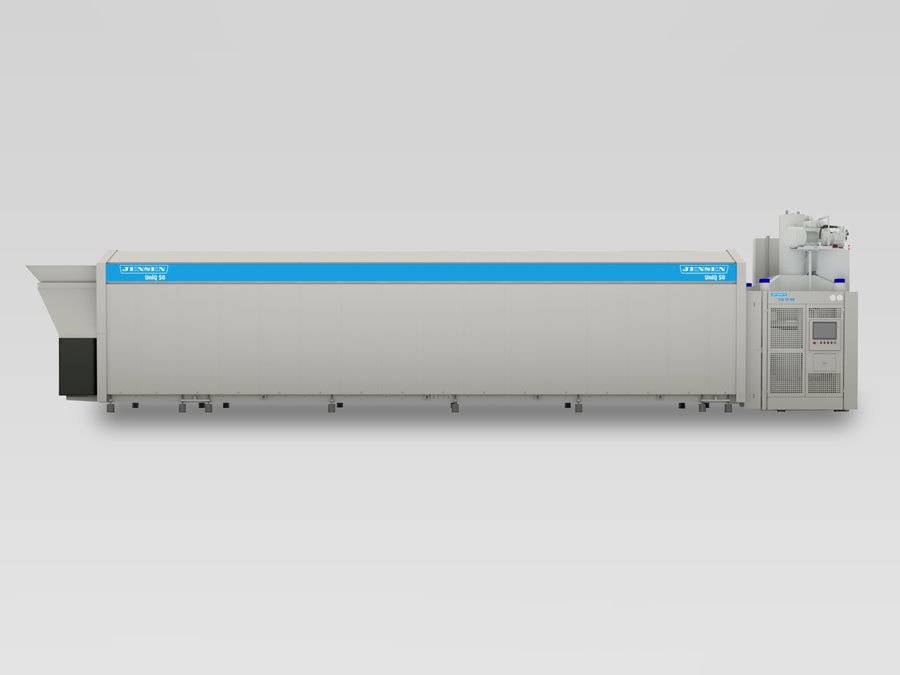

UniQ Tunnel Washer: Water and action

At the heart of the ride is the exclusive Archimedean helix inner drum, delivering superior drum strength, reliable batch transfers, and 285° of powerful mechanical action, for a better clean. The UniQ tunnel washer features QuickSoak which offers a gentle pre-wash shower power.

Lastly, there are no worries of recontamination, as UVClean technology prevents bacterial growth in the rinse double drum.

The Silverline and Classic Folders: The folding frontier

Behind the Express Pro, the Classic Folder delivers high-speed, high-accuracy folding in one- or two-lane operation. Its new space-saving design features built-in in-line stackers.

Just down the track, the Silverline pairs with the KliQ Feeder to offer the highest folding flexibility in Jensen Land. The cross fold section operates without pickups or drops, and this constant support means it handles both heavy and light linen with ease. It also features space-saving built-in stackers.

Metricon garment handling: The uniform loop

Hold on tight, the uniform loop is sweeping through Jensen Land with garment sorting and handling at lightning speed.

At the center of the loop is the all-new MetriRead Pro which will debut at the Jensen booth. With its high-speed RFID tunnel that reads garments with speed and precision on the fly, the MetriRead Pro boosts productivity right from the start. From there, the action moves to the Fox 1200, the fastest garment folder on the market, bringing speed and quality together in one unbeatable finish.

Every ride needs a strong launch, and garment handling is no different. That’s why we are showcasing two loading stations:

MetriQ, offering the highest levels of operator flexibility thanks to product-specific loading height and hanger orientation. It’s the most ergonomic and therefore most productive loading station for workwear in the industry. Its companion, MetriV, is built for maximum efficiency and an unbeatable cost-to-performance ratio.

Butterfly Classic: The lateral fold blast

Jensen’s #1 towel folder has been refined with a sharp focus on efficiency, simplicity, and accessibility. The lateral folds are powered by air blast and a new crossfold section makes maintenance a breeze. Furthermore, the upgraded interface puts ease-of-use front and center: we streamlined key components, like icon-driven user operation, to make operation more intuitive for every user.

The most powerful QR code in the industry: The quick Queue-R

A new revolutionary concept at Jensen Land allows you to skip the lines and get to your attractions as fast as possible. In fact, some are calling it the most powerful QR in the industry. The feature is highlighted on the Butterfly Classic towel folder. A simple scan immediately offers access to all aspects of machine management including manuals, spare parts, and work history. Additionally, you can make direct video calls to troubleshoot equipment, request support, or even place orders for spare parts.

By eliminating waiting times and extra steps, the Quick Queue-R (QR) allows you to maximize your equipment performance and manage your Jensen assets more easily than ever.

Don’t miss the cocktails, dancing, Latin food

When the show floor closes, the real party begins. Join us for our famous Jensen cocktail party, a night of dancing, drinks, and connection. It’s the most talked-about event of the Clean Show for a reason.

Great venue, great music, great people: Stop by the Jensen booth to pick up an invitation.

Make Jensen Land your first stop

If you are ready to level up with proven automation, enter the digital age, and partner with a team that gets it, start by creating the future in laundry automation with Jensen.

We look forward to seeing you at the show.

BOOTH 2609

Pellerin Milnor invites you to join us at The Clean Show in Orlando to discuss our trusted and sustainable laundry solutions. We will proudly display our state-of-the-art industrial laundry equipment that operates in laundries around the world.

This year, our booth will feature a 76039 PulseFlow® technology tunnel alongside various ancillary systems and materials handling machinery. Attendees will also get a firsthand look at how PulseFlow technology works through an interactive demo unit and can be the first to view our Total Plant Integration concept that addresses key issues in high-volume U.S. laundries.

Highlights of our Total Plant Integration solution include reducing congestion through hanging unsorted linen and AGV cart management, Milnor’s MilRail® sling system with Bin-to-Conveyor-to-Bag or Sort-on-Rail sort deck arrangements (also available in sling cart and simple loop solutions), a G6 CBW® washer in several different batch sizes, and a rotary drum filter, which will also be on display, to improve wash lint removal.

A Hands-Off Processor replaces barrier washers, and a Near-Zero™ dryer lint system significantly reduces airborne lint. The plant includes ergonomic linen presentation to finishing operators, while robotic integration handles towels and small pieces. Full data integration connects with third-party ERP systems for seamless processing.

We will also display a broad range of rigid and soft-mount OPL washer-extractors, including our brand new MWS26Z Staph Guard® machine. Attendees will have a chance to view Milnor classics such as the 27 kg capacity 30022VRJ, corresponding M758V dryer, 63 kg capacity 42026V6Z, and 77 kg capacity 42032X7R.

The Milnor team is excited to discuss our commitment to sustainable laundry solutions for North American laundries and all of the ways Milnor equipment benefits laundries of all sizes.

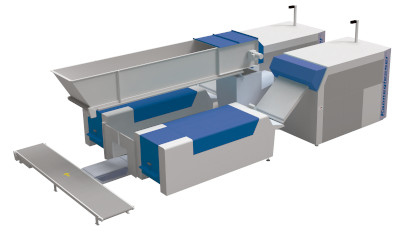

BOOTH 2037

Featured at the Clean Show is the Cube tunnel finisher. It delivers steam and air mixing throughout the entire machine leading to an improved garment finish. Active interior walls force steam and air onto the garments from the sides increasing wrinkle removal.

The Cube’s bi-directional layout allows garments to enter or exit from either the side or end of the tunnel, providing flexibility in plant layouts. The Cube easily expands by offering production rates of 1,000 to 5,000 pieces per hour.

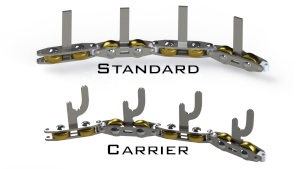

We will also have our popular CFS 90 narrow body tunnel, and the Colmac manufactured pendant and carrier chain. This chain features proprietary material selection, and the unique design of the carrier pendant, allows the hanger to smoothly slide when transferring between conveyors.

Colmac also manufactures triple buck shirt presses, custom pendant conveyor components, 180° drives, stainless conveyor tube, customizable polycarbonate conveyor safety guarding kits designed to fit most conveyor layouts, automated hanging systems, operator count stations, and hanger stands.

From innovative tunnel finishers, to conveyor chain systems, Colmac is intent on raising the bar in your plant.

BOOTH 2523

At Clean Show ‘25 Girbau & Girbau North America (GNA) will showcase the company’s vast product offering as the industry’s most diverse provider of vended laundry equipment and solutions, according to President Mike Floyd.

“During Clean, we promise new product introductions, engaging in-both interactions and valuable opportunities to interface with company staff, customers and distributors,” said Floyd. Attendees will also enjoy aggressive financing and product promotions, along with captivating live entertainment.”

New Product Introductions

GNA will unveil several new products during Clean, including GS Series 90- and 130-pound capacity washers, new ExpressDry Dryer capacity offerings, and the new Genius ExpressClean storewide soap delivery system.

New GS Series Soft-Mount Washers in 90- and 130-pount Capacities

The entire line of newly enhanced GS Washers (23- to 130-pound capacities) bring enhanced 450 G-force extract speeds, the highly intuitive Genius hybrid control, the industry’s largest 10-inch touchscreen, 360° Vision Corner Status Light and an easy-to-install freestanding design. The hybrid Genius Control switches from a customer-facing vended user interface and programming to an attendant-facing user interface with sophisticated commercial programming. This is useful for processing WDF and commercial account orders.

“Not only are we introducing the larger GS Washer capacities, the entire GS line is significantly improved with Sapphire laundry management and connectivity that includes monitoring diagnostics and remote programming, among other features,” said Vice President of Sales Joel Jorgensen. “These are highly productive machines that remove more moisture during extract for greater customer cycle rates, reduced stress on dryer capacity and efficiency.” All GS models, from 23- to 130-pound capacities will be featured with touchscreen/programming demos.

New ExpressDry+ Dryer Capacities

ExpressDry+ Dryers simplify installation and ease of use, drastically reduce gas consumption and downtime and boost profit potential. Reliable and efficient, ExpressDry+ Drying Tumblers are available in 30-, 55- and 75-pound capacity single-pocket units, and 30- and 45-pound capacity dual-pocket stacks. New model capacities will also be featured.

Genius ExpressClean

A new storewide soap/chemical delivery solution at the point-of-sale will also debut. This system – Genius ExpressClean works with the Genius Control – making it simple to offer multiple choices of detergents, color safe brighteners and softener options sold and delivered automatically to customers during their cycle. “Genius ExpressClean is another way to create customer convenience while reducing staff clean-up time and boosting total store revenue,” said Jorgensen.

Washers, Dryers and Ironers in the Booth with Demos

Besides the full lineup of GS Washers and Genius ExpressClean, Continental’s booth will offer demos and more to explore. Booth visitors can view an “out-of-balance” demo on the GS 70-pound capacity washer and the fully operational Express Flatwork Ironer with a 20-inch diameter roll.

Express Flatwork Ironer

The Express Flatwork Ironer is often used by vended laundries to iron sheets and table linens for commercial and residential WDF and pickup and delivery orders. Express Flatwork Ironers properly finish up to 50 feet of linen per minute. Available in 13- and 20-inch roll diameters and up to 125-inch finishing widths, Express Flatwork Ironers offer enhanced processing speeds; an easily accessible lint cleanout; a wide, metallic feeding tray; reinforced lateral bearings; and multiple heating systems. Making the most of available space, these return-to-feed ironers can be installed 12 to 18 inches from a wall.

G-Flex Hard-Mount, ExpressWash Soft-Mount Washers

The G-Flex 200-G-force hard-mount and the ExpressWash up to 405 G-force soft-mount washers will also be on hand.

To learn more about GNA’s products, services or career opportunities, visit gnalaundry.com or call 800-256-1073.

BOOTH 2469

Gurtler Industries, Inc. is a leading manufacturer of advanced detergents and specialty chemicals for the commercial laundry industry. Founded in 1982, Gurtler is a privately held, family owned and operated business, with three generations of the Gurtler family in our organization.

Gurtler has grown into one of the largest specialists in the laundry chemical supply industry, offering a full line of processing chemicals, injection systems and personalized service across North America, the Caribbean and Australia. Our programs are uniquely designed to support all segments of the laundry industry, including: • Industrial Uniform • Linen Supply • Healthcare • Hospitality.

Our company’s success has been built upon our expertise in field service. Gurtler is dedicated to maintaining excellence throughout our organization and sharing that commitment with our customers. The Gurtler family has made their personal commitment to service, innovation and people. That is what has made Gurtler’s reputation what it is today. Visit our booth and meet some of our Gurtler Experts.

Featured at our booth will be our exclusive, patented Vis-Tex Tunnel UV System that uses UV and activated oxygen technology to treat your tunnel reuse water, assuring brighter whites, reduced water and utility costs and hygienically clean textiles. Also featured are Gurtler’s Vis-Tex liquid chemical dispensing systems, exclusively designed and manufactured by Gurtler’s expert engineers. The Vis-Tex family of dispensers include unique production data monitoring capabilities and flow meter technology for both tunnel installations and traditional washers, delivering the right amount of laundry chemistry at the right time, every time.

BOOTH 1422

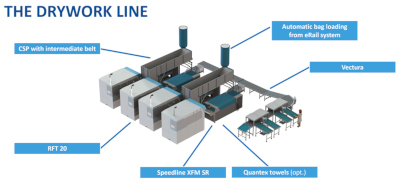

The RFT is Changing the Game of Laundry Automation!

Can robotics truly revolutionize the laundry industry? The Kannegiesser RFT Dry Work Line is here to prove that it can. Combining 3D camera technology, intelligent image evaluation, and ServoTronic robotics, the RFT Dry Work Line ensures high process speed, precision, and constant control. Capable of handling an impressive 600-800 items per hour with 2-3 batch changes per hour, this system is designed to meet the growing demand for automated solutions in laundries worldwide.

With over 65 units already in live production across Europe, the RFT Dry Work Line has consistently demonstrated its effectiveness and reliability. Now, as we introduce this advanced technology to the North and South American markets, it is set to elevate laundry production to new heights, delivering exceptional results for our customers.

How can the RFT Dry Work Line enhance your laundry operations? When designing the RFT, our engineers meticulously considered variables such as shrinkage, performance factors, and quality control. The result is a process and design that addresses the intricate details laundry operators face daily. The RFT operates smoothly in demanding environments, performing clean side feeding and folding without needing employees. This feature is especially valuable in European laundries, where the machine has already shown its effectiveness in multi-shift operations. By automating these repetitive and tiring tasks, the RFT provides a reliable solution for operators struggling to find staff for such roles.

What can robotics do for my laundry production and teams?

- More Employment in Other Laundry Areas: By automating the feeding process, employees are free to perform other important tasks such as quality control or preparing and inspecting items in pack-out areas ready for delivery.

- Steady Performance: Consistent feeding performance, preventing the process from becoming a bottleneck and maintaining productivity throughout production.

- Wide Range of Articles Processed: The Dry Work Line can handle batches of up to four different articles that vary in width or length without compromising productivity. The optional ColorSort function allows for sorting different plain-colored articles that don’t differ in size.

- Recognition for Employees: Working with robotics and intelligent control systems builds your team’s satisfaction. Recruiting for a modern laundry becomes easier as employees appreciate ergonomic workstations and take pride in being part of an innovative and forward-thinking company.

To learn more about how the RFT Dry Work Line can transform your laundry operations, reach out to our sales team today. Contact us at info@kannegiesser-etech.com or call us at 612.722.1366.

BOOTH 1303

Lavatec to emphasize superior equipment performance and longevity

Lavatec will demonstrate an LT60 eight compartment bottom transfer tunnel washer with 132-pound capacity per chamber; an LX-445 washer extractor with 450-pound capacity; an LP572 LavaPress single stage extraction press which improves workflow by handling 132-pound loads using up to 40-bars of pressure; and three premium and energy efficient gas dryers: the TT745, TT757, and FL633.

On the finishing side, Lavatec will showcase innovative equipment from Vega Systems. As Jim Shaw, Lavatec’s Vice President and National Account Sales Manager explains later, the four versatile machines to be displayed represent a cross-section of cost efficient systems that are designed to produce a better finished product for customers.

Customers who know best

The ability to have equipment perform impressively and reliably day-after-day for 25 years or more requires a series of events. A few Lavatec customers who plan to attend the show understand the connection. They say it begins with having the craftsmanship to design and build a custom-made machine, and supporting it with a well-trained group of employees who run and maintain it properly.

Patrick Garcia, president and CEO of Division Laundry & Cleaners in San Antonio, Texas, knows all about the longevity of Lavatec’s equipment.

“Back in 1995, we traveled the United States to see the tunnel washer options that were available at the time. Our general manager had been our chief engineer for 30 years, so he pointed out all the maintenance advantages and the differences in the craftsmanship between the thickness of the steel and welding,” recalled Garcia. The family owned and operated company has been in business for 86 years.

“We were impressed with the Lavatec systems. Now, 30 years later, our 16 module LT60 with a steam heating system and the five dryers we purchased from them are still in operation. We knew by committing to having a strong maintenance program in place, it would help extend the lifecycle of the equipment.”

Metropolitan Detroit Area Hospital Services (MDAHS) became a Lavatec customer in 2007. By upgrading their tunnel wash systems and dryers four years ago, the downtown Detroit state-of-the-art facility has vastly improved their energy usage and efficiency.

They replaced their original LT50 system with 14 compartments and 110-pound capacity, with two new LT100s. The second largest continuous tunnel washer Lavatec manufactures (only the LT120 exceeds it at 250-pound capacity) these machines boast 220-pound capacity and 12 modules are joined on the floor by 16 TT745 natural gas dryers and the LP583 LavaSpeed extraction press. All are monitored by Lavatec’s intelligent osLaundry data management information system.

“While I am new to this facility, I am very familiar with Lavatec’s tunnels and dryers having managed them in two previous plants,” said Cecil Lee. A 38-year industry pro, he joined MDAHS as the general manager last November and expects his facility to process 34.9 million pounds of laundry this year.

“We are incredibly pleased with the washers’ performance and dependability. Our water usage has dropped from 1.01 gallons to 0.67 gallons per pound. This is a .3447 gallons per pound savings as we are producing greater than 34 million pounds of linen annually.

“When dryers work properly, they keep work in front of the processors during the spring, summer, fall and winter,” he continued. “The Lavatec dryers continue to perform efficiently and, to my amazement, dry loads properly even with various degrees of dryer basket cover such as the plastic disposable under pads that were not sorted properly. We have reduced both our therms per pound and our kilowatt hours per pound.”

The Portland Hospital Service Corporation’s pair of LT70 bottom transfer tunnel wash systems in Oregon have been the very definition of “dependable” for 23 years. The 18 module, 154-pound capacity machines produce an impressive amount of washed linen annually. They also have rolled up a staggering amount of hours and are closing in on the 150,000 mark.

“From an engineering perspective, Lavatec tunnels are very reliable and continue to meet our laundry processing needs after 23 years. Our continuous batch washers (CBW) and Lavatec dryers handle 110,000 pounds of linen six days a week with little to no interruptions,” said chief engineer David Rowning. The hospital has served the community in the northwest region since 1970.

General manager Shawn Swingholm said the Lavatec equipment currently operates 14 hours a day, six days of the week. Between July 2024 and July 2025, he reports the CBWs washed 34,130,540 pounds of linen, which equates to 114,104 batches divided between the two washers.

Introducing Vega Systems Finishing Equipment

Lavatec will showcase its new partnership with VEGA Systems by featuring flatwork equipment in booth 1303. All four machines – the Vega Transfeed 3S1, VegaFold 2S, Vega Multifold Super 2.2 and Vega Multifold 4S – match Lavatec’s solid reputation for high performance, productivity and reliability.

The VegaFold 2S and VEGA Multifold Super 2.2 flatwork equipment in Lavatec’s booth will give laundry operators solid options for a better finished product.

“This equipment gives any size laundry operation the ability to improve the finishing side of their business. Each machine serves a valuable function,” said Jim Shaw, a longtime laundry industry professional who knows better than anyone. He served as the president of VEGA Systems USA for nine years before joining Lavatec in 2023.

“For example, the VegaFold 2S conserves space and sort textiles to deliver the best finished product,” continued Shaw. “While the Vega Multifold Super 2.2 will process larger, full dry products with precision using positive folding functions, the Vega Transfeed is designed for smaller piece feeding. It combines a system to deliver flatwork to the ironer with the flexibility to convert the processing with high production to yield a better finished product.”

A high-speed, three station feeder system capable of processing sheets, heavy duvet covers, and high quality table linens, the Vega Transfeed sports a working width up to 157-inches wide. It offers up to four large-piece adjusted height clipping stations, a combination of one or two feeding lanes for large pieces, and a movable feeding bed with multiple lanes for manual feeding.

The VegaFold 2S is built to accommodate a wider cross-fold section. It can process large pieces with only two lateral folds and has a third lateral fold option. It saves valuable floor space since it is equipped with two automatic standard sorting stackers inside the machine frame, with an optional third automatic sorting stacker. Two separate air pressures are designed for thicker and thinner linen.

The Vega Multifold Super 2.2 is a high quality full-dry folder. It makes all lateral folds with mechanical knives to handle thick terry and heavy, full-dry products, and all cross-folds are performed by reverse belt folding technology. With a processing capability up to 86-inches long, Multifold Super is available with three or four automatic sorting stackers, thereby eliminating the need to pre-sort full-dry items by size. All finished stacks are either directed to an operator or ready for automatic transfer to a take-away conveyor.

The Vega Multifold 4S is a towel folder, sorter, and automatic stacker that many commercial laundries prefer. It handles a variety of towel sizes, can be configured for different folding needs, and performs lateral folds with air knives and all cross-folds using belt reverse folding technology. Like the Multifold Super, it can handle items up to 86-inches long with automatic sorting up to four sizes. It can also be configured for manual or automatic transfer of stacked goods.

Don’t miss the Hall of Fame ceremony

A reminder that all Clean Show attendees are invited to watch the inaugural class of Lavatec’s Hall of Fame be inducted. The 30-minute ceremony will take place in booth 1303 on Sunday, August 24 at 3 p.m.

BOOTH 3123

Miele is proud to showcase cutting-edge technologies and sustainable solutions that are shaping the future of commercial laundry.

Whether you’re running an on-premise laundry or managing a large-scale textile service operation, Miele has the tools to elevate your business.

The countdown is on — we can’t wait to see you at our booth #3123!

BOOTH #1357

Visitors are invited to explore a wide range of commercial laundry solutions at booth #1357, where Whirlpool Corporation will spotlight Maytag Commercial Laundry and ADC brands in an immersive, market-segment-themed environment.

The booth experience will feature real-world laundry settings designed to reflect three core segments:

- A vended laundromat spotlighting the benefits of a Maytag Equipped Laundry.

- Laundry State, a college-inspired multi-housing laundry room featuring equipment built for shared-use environments.

- A hotel lobby that doubles as a meeting space, while showcasing the business needs of on-premise laundry operators.

A fourth featured section will be dedicated to ADC, highlighting the brand’s high-capacity drying technologies and standout options for OPL and specialty solutions.

Clean Show attendees will discover the following products at this year’s Whirlpool booth.

- AD-120i OPL dryer

- AD-758V OPL dryer

- MHN33PRCWW single front load washer

- MLG36PDAWS multi-load 30# stacked dryer

- MDG80PDAWS 80# multi-load dryer

- AD-210 industrial dryer

- ADFG firefighter’s turnout gear drying cabinet

“Clean Show is a great opportunity to connect with our customers, listen to their evolving needs and demonstrate how our solutions are built with their day-to-day operations in mind,” said Michael Ledford, senior director and general manager, commercial laundry. “We’re excited to bring these environments to life and offer a look at where commercial laundry is headed next.”

In addition to hands-on access to the latest equipment, visitors can expect a few surprises throughout the space, making booth #1357 a must-visit destination during the show.

CALL FOR CLEAN SHOW

BOOTH INFORMATION

If you have reserved a booth at the Clean Show in August, we want to know about it! Send us a description of what you will be showing and a few photos. We’ll include it in here. Don’t forget to include your booth number. Send it to becca@fabricarecanada.com.