Clean Show 2025 Diary – Day 2

By Becca Anderson

CLICK HERE IF YOU MISSED DIARY DAY 1

Following another fine breakfast buffet meal, I was ready to tackle the thousands of steps necessary to get back to the Show. Again, I began with a seminar.

Sneak Preview

The Textile Rental Service Association (TRSA) had a great program called Innovation, Automating & Digitization: What’s New and Important on the Show Floor. I suspected this would save me a lot of time, and I was not wrong.

The association asked Clean Show exhibitors to send in information about the most innovative things in their booths ahead of time. Then a group of experts went through them to narrow down the choices. Those experts spent Saturday visiting the booths left on their lists and evaluating the innovations, and brought their discoveries to us.

The experts found everything from some of the innovations I enumerated in my Diary from Day 1 yesterday to Becks Classic embedding copper in bed pads to kill bacteria and neutralize PH, to micro wave dryers from Unitex International, to UV light cart sanitizing systems, to patient gowns that tie down the side instead of in the back (no more flapping open!), to Tingue’s new website that features a NAPA Auto Store style parts store with over 7500 new SKUs covering all major manufacturer’s parts, and more. It was great to hear why each innovation was important and caught their attention.

Back to the Floor

Entering the Clean Show means you enter the Seitz booth – it’s right in front of you. I stopped by to say hello to Alexander Seitz and chat with Kurt Wickiser about new items in the booth. One that he cited is VivaGeniox, a new detergent for both wet cleaning and commercial laundry applications that can handle both ends of that spectrum.. “From wet cleaning to the dirtiest commercial laundry,” he said.

I also wandered into the Cleaner’s Supply booth and spoke to Jeff Shapiro. Spoiler alert! We spoke about them carrying and item that Fabricare Canada is producing. Stay tuned for news about that soon.

In the Milnor booth I got the full tour of the latest and greatest, including a rotary drum filter that reduces redeposition from tunnel washer water. It eliminates the need for a shaker screen.

Also in the booth were an updated MilTouch Controller which now is instantly touch-sensitive like a cell phone, without a time delay. In the same vein, the screen used to be almost overloaded with details. With a touch of a button, it moves to a simplified view of operations. This was an innovation requested by customers, and Milnor took it to heart.

An Aseptic Barrier Washer/Extractor was on display for healthcare laundries. Dirty clothes go in one side, clean come out the other, and a barrier keeps contaminated air from crossing over and recontaminating the load.

Finally, the company is working on “total plant integration” for healthcare laundries (with plans for a hospitality version later) to give a complete array of equipment for a plant, partnering with Chicago for the finishing side.

There was a new face in the GreenEarth booth, as Tim and Karen Maxwell have now retired.

Tony Chvala is now in Tim’s old role, and we had a chance to talk about his background and his vision for the future of GreenEarth. We’ll be featuring a profile about Chvala to help you get to know him in an upcoming issue. And stay tuned for big news on a huge project from GreenEarth in the next month or so!

I came across the Laundry Luv booth, and talked to Nate Carter. His company franchises laundromats. Rather than a newbie to the field fumbling around and making rookie mistakes, they can pay a franchise fee and get valuable assistance with site selection, equipment selection, marketing, training and much more. Right now, the company only has locations in Texas, but hopes to branch out across the US eventually.

Our discussion centered on the many ways that people come into the laundromat branch of the industry, and how his company was offering a logical option for those who needed extra help to be sure they would be successful.

Awards!

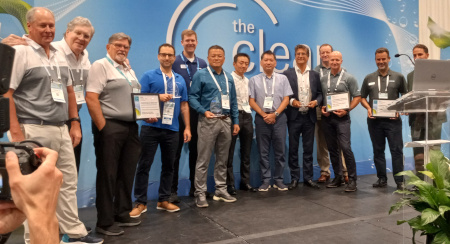

There were two awards presentations at the Show (so far). The first was from the Clean Show itself, as it gave out Innovation Awards to companies the Show selected as leaders in the areas they wanted to highlight.

Awards included:

- Best New Product

- Best New Application

- Best New Technology for Sustainability

- Best New Technology for Automation

I will try to have the winners list for you tomorrow. The ceremony was enthusiastic, and it was impossible for me to both take photos and get down company names, product names and award categories. Check back then.

The other awards given were in a press conference in the Lavatec booth. The awards honored long-time customers who have demonstrated the solidity and longevity of Lavatec equipment day-in and day-out for many years.

Winners were:

- Cintas – Lavatec’s oldest customer, that has installed more than 1000 of the company’s machines across the US in the past 35 years. This number represents about 12 percent of all Lavatec installations in North America.

- Division Laundry of San Antonio, TX (accepted by Theresa Garcia). The company put in a Lavatec tunnel system 30 years ago, and it’s still operating. Through strategic decisions, the company saved over 35 million gallons of water in 2024 alone.

- St. Francis Hospital, Tulsa, OK (accepted by Mario Villareal). The company has a Lavatec tunnel system that has run 13 hours a day for so long it’s racked up 145,000 hours, by best estimate. They’ve recently completed a new laundry facility to serve the hospital and other customers.

- Metro Detroit Area Hospital Services, in Detroit, MI (accepted by General Manager Cecil Lee). Though their new facility opened 5 years ago just as COVID dominated the world, they have managed to decrease water and energy usage each year, and processed 34 million pounds of laundry last year.

- Bay State Linen, Boston, MA (accepted by Greg Decious). The company is continually pushing the envelope to improve operations.

- Portland Hospital Service Corp., Portland, OR (accepted by General Manager Shawn Swingholm and Chief Engineer David Rowning). The plant has been running one of Lavatec’s tunnel systems 14 hours a day, 6 days a week. They processed 34 million pounds of linen last year.

- Vinny Samuel was recognized for individual achievement, as President and Co-Owner of JVK Operations, with facilities in New York and New Jersey. Described as having “one of the sharpest engineering minds in the industry,” he started as a plant engineer 40 years ago. One of his tunnel systems has been running day-in and day-out for almost 30 years.

To further honor and thank these distinguished customers, and other Lavatec customers, the company held an informal reception at a restaurant nearby, and I was invited. There I had a chance to hear more about the extensive new plant that St. Francis has built.

Another long day, but a good one. Tomorrow will be another full schedule of booth visits, interviews and education. Check back to hear all about it!

Related Posts

-

Change the World — One Load at a Time

No Comments | Nov 12, 2024

Change the World — One Load at a Time

No Comments | Nov 12, 2024 -

Virtual Mini Show

1 Comment | Aug 11, 2020

Virtual Mini Show

1 Comment | Aug 11, 2020 -

What a great party!

No Comments | Jul 31, 2022

What a great party!

No Comments | Jul 31, 2022 -

Five Trends Reshaping the Laundromat Industry in the US and Beyond

No Comments | Aug 8, 2023

Five Trends Reshaping the Laundromat Industry in the US and Beyond

No Comments | Aug 8, 2023

About The Author

Editor, Fabricare Canada magazine

Becca Anderson spent 17 years in public relations, advertising and corporate PR before joining Fabricare Canada in 2000. She was named editor in 2013, and welcomes feedback about the magazine via the contact form on this site.