Buy Yourself Some Magic

“Any sufficiently advanced technology is indistinguishable from magic.” – Arthur C. Clarke

By Kevin Marois

This is a great time to be in this industry. We have equipment that reduces the strain on your workers. It allows you to use less skilled staff but still produce well finished garments. These machines and chemicals will save you labour – if you are willing to use them.

Your customer may think you do magic when you restore their favourite garment or get a wine stain out. But there is no magic in dry cleaning – just modern technology and well trained technicians.

Unfortunately, many in our industry bury their heads in the sand and refuse to consider something new that will make their work easier and give even more professional results. In case you are one of those individuals, let me list a few things that you might think are magic.

Air Dryer

How about a machine that will free your mechanic from having to lubricate the valves on your dry cleaning and shirt machines? An air dryer uses refrigeration to condense moisture out of compressed air.

Over time, moisture will flush the lubrication out of air solenoid valves. The valves are slower to move or may not move at all. That throws the timing off on your shirt unit and your shirts look terrible. Or maybe the valves on your dry cleaning machine stick open (or closed). You might be trying to pump solvent into the wheel and it goes into a tank.

The worst part is that these problems are intermittent to start with. Once it becomes a serious problem, it is already too late. Most of the valves are dry and erratic in their operation. An air dryer might cost a couple of thousand dollars, but that isn’t much compared to having a technician repeatedly visiting your plant.

You could also get automatic drains on the air regulators on your machines. It works like magic: whenever it fills with water, it drains automatically.

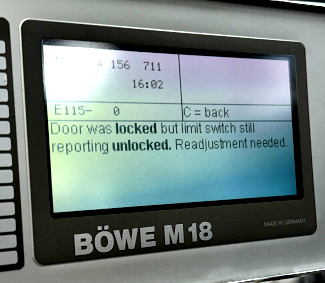

Self-Diagnostics

We now have machines that tell you when there is a problem – and they tell you what the problem is. The only thing better would be a machine that fixes itself. (Of course, then I’d be out of a job and you’d have to find something else to worry about.)

Most new machines will display an error code when there is a problem. Some will list a history of problems so you can observe a trend of what is happening. Error codes are listed in the manual, as well as the procedure to recover from the problem. This often gives a clue whether it’s something you can fix yourself, or that you need a technician to handle.

Despite the machine being smart enough to know what is wrong and telling you about it, some operators appear to be incapable of reading the code and passing on that information to their mechanic. When you go to the doctor, do you tell him/her where it hurts or do you make them guess? If you want to save money, give me good information. Often we hear, “I just turned it off and it started working again.”

Washers

We have a lady who only has one cycle on her washer. I guess everything is a comforter. She is happy but she is missing out on so much.

Soft-mount washers have high-speed extracts to reduce the time in the dryer. They have sophisticated computer controls that allow cycles for every type of soil you face. They have inverters (or frequency drives) to give you complete control over the wash and extract speeds.

Chemicals are flushed into a sump and mixed with water before it contacts the fabric – that is critical for wet cleaning. Some washing machines weigh the load and adjust the amount of water and detergent to match the load size. Why would you not want all that?

Magical Chemicals

These chemicals are legal even though they do make you feel happy when you use them. Detergents specifically tailored for specific soils and fabrics. Texturizing agents that restore softness and body to fabric. Environmentally friendly solvents that are safe for your staff and yet are still effective.

There are detergents now that use ions to cause the fabric to repel the soil. Then there are coatings that stop soil from penetrating the fibres so they are easier to clean. How about wet cleaning detergents that allow you to process wool in water and then put it in the dryer – and not worry about shrinkage. That has got to be pretty close to magic, but some cleaners use it every day. Why aren’t you one of them?

Are they more expensive? Yes. Chemistry costs money. Research is expensive. But if they are saving you wages and putting out a product that makes your customers happy and keeps them coming back, they pay for themselves.

Trained Technicians

The theme this month is Mechanical Magic – that is what my guys do every day. Boiler is down, dry clean machine won’t dry – sorry, that’s just another day at the office for our techs. Why? Because they work hard at improving their craft.

We hold monthly training sessions, including homework and exams. We disassemble old machines to find faster ways to do repairs. We even have trainers come from our manufacturers to train our technicians.

We do all that so that when we come to your plant, you are amazed at how easily we turn your nightmare into just another day at work. No matter how it looks, we don’t do magic – just hard work.

Amazing Equipment, Chemistry and People

If you have a situation that truly requires magic, speak to your equipment supplier. There may not be an off-the-shelf solution, yet, but equipment manufacturers survive by solving problems. Let them know what difficulty you have and let them work on it. Maybe with their help you, too, could soon be performing magic.

Kevin and Paula Marois founded Calgary-based Integrity Mechanical in 2003 to service plants in western Canada. He writes on issues related to equipment, its purchase, maintenance and use. You can reach Kevin at office@imicanada.ca or via his website www.imicanada.ca